ISO 5954:2014 pdf download.Cold-reduced carbon steel sheet according to hardness requirements

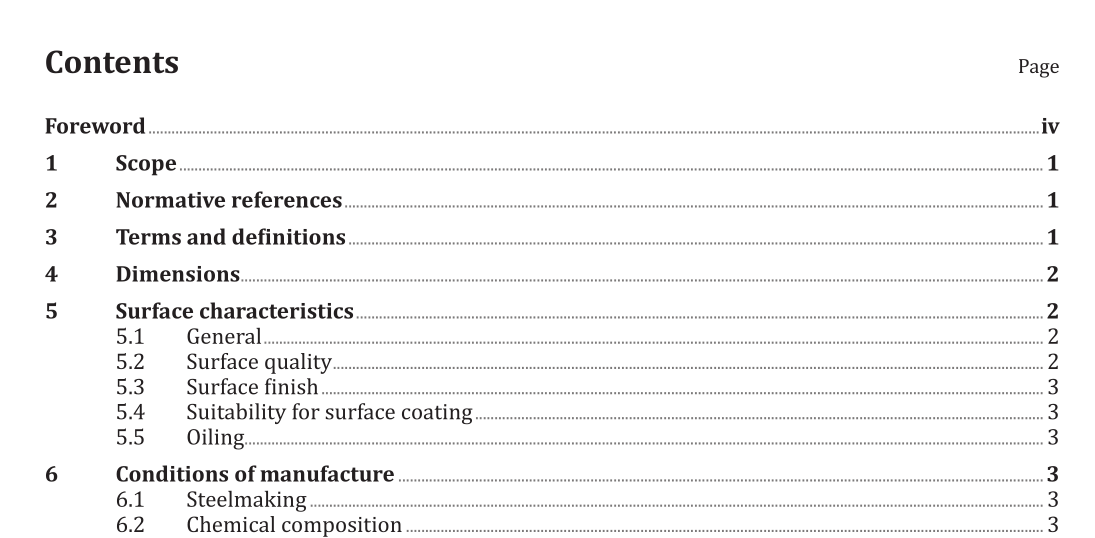

1 Scope

This International Standard applies to cold-reduced carbon steel sheet and corresponding hardness requirements. It is suitable for applications where the surface is of prime importance.

The following are common hardness ranges (see 6.6):

— CRH-50: Rockwell B 50 to 70;

— CRH-60: Rockwell B 60 to 80;

— CRH-70: Rockwell B 70 to 90;

— CRH-NN: Any Rockwell B range of 20 points up to and including HRB 90 maximum (designated minimum of specified range will be shown).

NOTE By agreement between the supplier and purchaser, Rockwell ranges less than 20 points can be specified.

This International Standard does not cover commercial quality or drawing qualities (covered in ISO 3574) and cold-reduced carbon steel strip.

2 Normative references

The following documents, in whole or in part, are normatively referenced in this document and are indispensable for its application. For dated references, only the edition cited applies. For undated references, the latest edition of the referenced document (including any amendments) applies.

ISO 6508 (all parts), Metallic materials — Rockwell hardness test

ISO 16162, Cold-rolled steel sheet products — Dimensional and shape tolerances

3 Terms and definitions

For the purposes of this document, the following terms and definitions apply.

3.1 cold-reduced steel sheet

product obtained from hot-rolled descaled steel sheet by cold-reducing to the required sheet thickness followed by annealing to recrystallize the grain structure

Note 1 to entry: The product is normally supplied in the skin-passed condition.

3.2 skin pass

light cold rolling of the product

Note 1 to entry: The purpose of the skin passing is one or more of the following:

a) to minimize the appearance of coil breaks, stretcher strains, and fluting;

b) to control the shape;

c) to obtain the required surface finish.

Note 2 to entry: Some increase in hardness and some loss in ductility will result from skin passing. Cold-reduced sheet supplied in the skin-passed condition tends to strain-age and this might lead to an increase in the hardness value. Because of this, the hardness values at the time of shipment will be the determining factor as to whether the hardness requirement has been met.

5.2.2 Surface quality B (exposed)

The better of the two surfaces shall be free of imperfections which might affect the uniform appearance of quality paint or an electrolytic coating (see 5.4). The other surface shall at least conform to surface quality A. In the case of delivery of coil and slit coil, the percentage of defects might be greater than in the case of delivery in sheet or cut lengths. This should be taken into account by the purchaser, and the percentage of admissible surface defects can be agreed at the time of the enquiry and order. Unless otherwise agreed, a single surface of the product shall comply with the specified requirements. The other surface shall be such that, during subsequent treatment, it does not have a deleterious effect on the better surface.

ISO 5954:2014 pdf download