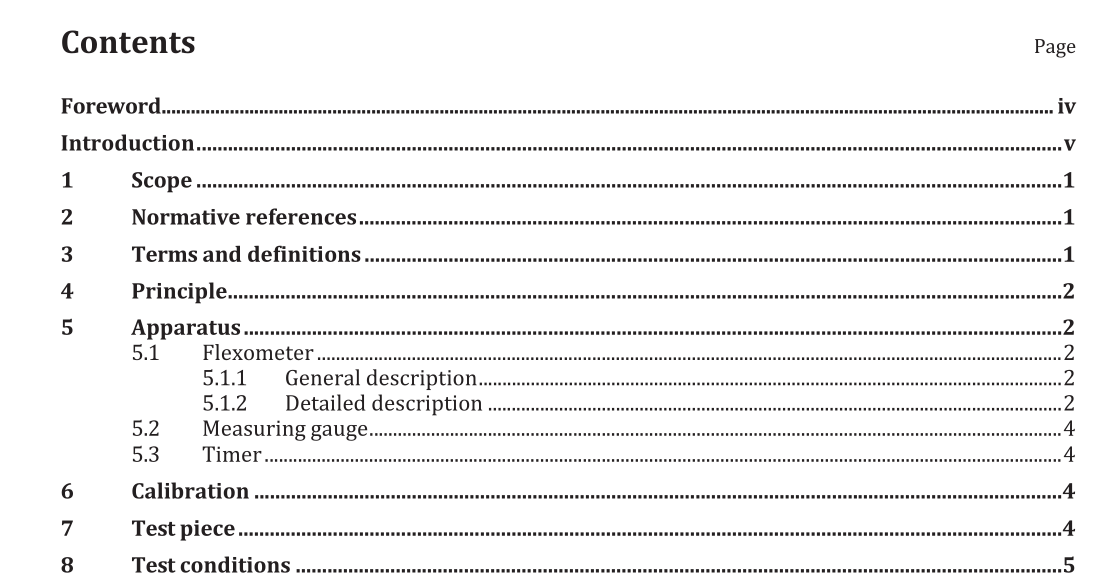

ISO 4666-3:2016 pdf download.Rubber, vulcanized — Determination of temperature rise and resistance to fatigue in flexometer testing

1 Scope

This document specifies the flexometer test with constant-strain amplitude for the determination of the temperature rise and resistance to fatigue of vulcanized rubber. The flexometer specified is known as the Goodrich flexometer, but any other apparatus giving equivalent performance can be used.

This document gives directions for carrying out measurements which make possible predictions regarding the durability of rubbers in finished articles subject to dynamic flexing in service, such as tyres, bearings, supports, V-belts, and cable-pulley insert rings. However, owing to the wide variations in service conditions, no simple correlation between the accelerated tests described in the various parts of this document and service performance can be assumed.

The method is not recommended for rubber having a hardness greater than 85 IRHD.

2 Normative references

The following documents are referred to in the text in such a way that some or all of their content constitutes requirements of this document. For dated references, only the edition cited applies. For undated references, the latest edition of the referenced document (including any amendments) applies.

ISO 48, Rubber, vulcanized or thermoplastic — Determination of hardness (hardness between 10 IRHD and 100 IRHD)

Rubber — General procedures for preparing and conditioning test pieces for physical test methods

ISO 18899:2013, Rubber — Guide to the calibration of test equipment

3 Terms and definitions

For the purposes of this document, the terms and definitions given in ISO 4666-1 apply.

ISO and IEC maintain terminological databases for use in standardization at the following addresses:

— IEC Electropedia: available at http://www.electropedia.org/

— ISO Online browsing platform: available at http://www.iso.org/obp

4 Principle

A specified compressive load is applied to a test piece through a lever system having high inertia, while imposing on the test piece an additional high-frequency cyclic compression of specified amplitude. Measurements are made of the increase in temperature at the base of the test piece with a thermocouple which provides a relative indication of the heat generated in flexing the test piece and of the number of cycles which produces fatigue breakdown. With the test piece subject to a constant applied load or to a constant initial compression during the test, continuous measurement is made of the change in height of the test piece. The compression set of the test piece is measured after testing.

The load is applied by means of a lever resting on a knife edge. The moment of inertia of the lever system is increased and its natural frequency reduced by suspending masses of 24 kg at each end of the lever system. The lower anvil can be raised or lowered relative to the lever by means of a calibrated micrometer device. This device permits the lever system to be maintained in a horizontal position during the test as determined by a pointer and a reference mark on the end of the bar.

ISO 4666-3:2016 pdf download