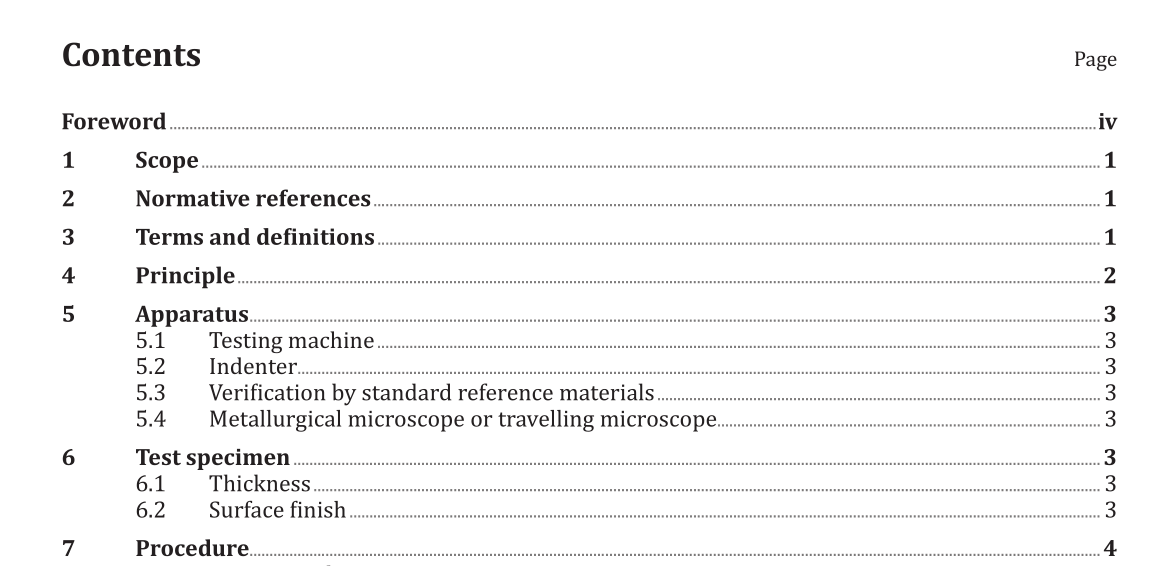

ISO 21618:2019 pdf download.Fine ceramics (advanced ceramics, advanced technical ceramics) — Test method for fracture resistance of monolithic ceramics at room temperature by indentation fracture (IF) method

1 Scope

This document describes a test method that covers the determination of fracture resistance of monolithic ceramics at room temperature by the indentation fracture (IF) method. This document is intended for use with dense monolithic ceramics and whisker- or particulate- reinforced ceramics which are regarded as macroscopically homogeneous. It does not include monolithic silicon nitride ceramics for bearing balls and continuous-fibre-reinforced ceramics composites. This document is for material development, material comparison, quality assurance, characterization and reliability data generation. Indentation fracture resistance, K I,IFR , as defined in this document is not to be equated with fracture toughness determined using other test methods such as K Isc and K Ipb . NOTE K I,IFR is an estimate of a material’s resistance to cracking as introduced by an indenter and has correlations with wear resistance and rolling contact fatigue performance as well as machining processes, since these properties are governed by the resistance to crack extension in localized damage areas [1]-[3] . By contrast, fracture toughness properties K Isc and K Ipb are intrinsic properties of a material and are relevant to macroscopic and catastrophic fracture events with long cracks rather than those phenomena caused by microscopic and successive damage accumulation associated with short cracks.

4 Principle

This document is for material development, material comparison, quality assurance, characterization and reliability data generation of dense monolithic ceramics. The method determines the indentation fracture resistance value, K I,IFR , from the elastic modulus and indentation force by forcing a Vickers indenter (diamond pyramid) into the surface of a test piece and measuring the lengths of both the diagonals and the associated cracks of the indentation that are left in the surface after removal of the indenter (see Figure 1) [4] . The method is applicable to the half-penny-crack type but not to the Palmqvist type. The two types of crack profile can be estimated using the ratio of the crack length, 2c, to the diagonal length, 2a. If 2c/2a is more than 2,5, the crack is half-penny type. But the critical 2c/2a values can be smaller than 2,5 for some ceramics. In such cases, direct observation of crack morphology by the decoration technique or serial sectioning of the indented surface is also useful to differentiate the two crack profiles. The measurement of the crack length and the observation of the crack tips are performed separately in order to improve the accuracy. The crack length should not be measured in a single optical image because doing so inevitably limits the magnification that can be used. Travelling microscopy is a solution that allows both reading of the crack length and detection of the crack tips to be performed at high resolution, albeit separately. Both an objective lens of 40 × or higher and a calibrated optical stage shall be employed to ensure reliability. Both international and domestic interlaboratory comparison study (round robin) projects on the advanced IF method are described in Annex C (see References [5] to [8]).

ISO 21618:2019 pdf download