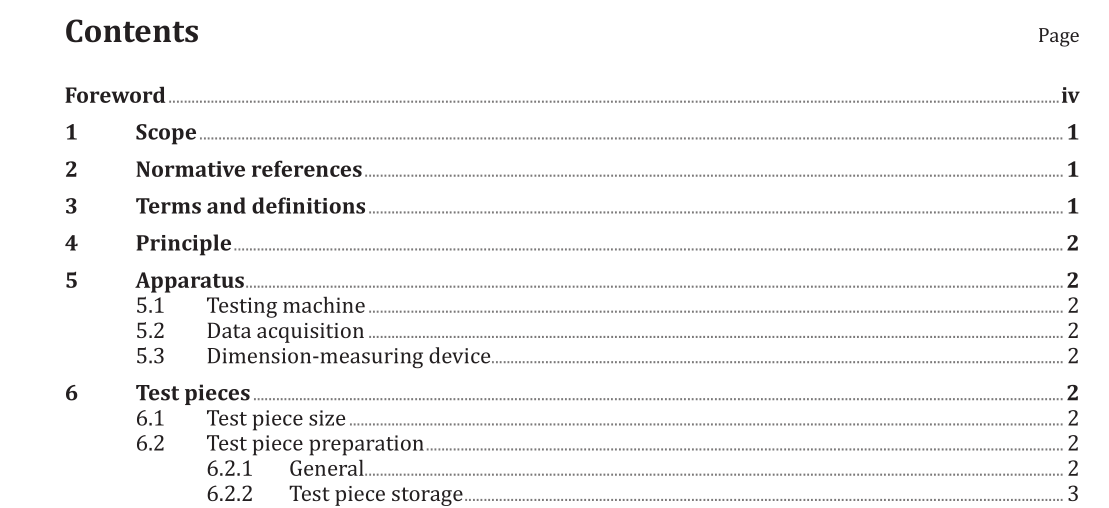

ISO 18558:2015 pdf download.Fine ceramics (advanced ceramics, advanced technical ceramics) — Test method for determining elastic modulus and bending strength of ceramic tube and rings

1 Scope

This International Standard specifies the testing method for determining the elastic modulus and bending strength of ceramic tubes or rings at ambient temperature by the compression tests on split ring pieces. Methods for test piece preparation, test modes and load rates, data collection, and reporting procedures are addressed.

This International Standard applies primary to the ceramic materials including monolithic fine ceramic,glass, whisker- or particulate reinforced ceramic composites, but not available for fibre reinforced ceramic composites. This test method may be used for material research, quality control, and characterization and design data generation purpose.

2 Normative references

The following referenced documents, in whole or in part, are normatively in this document and are indispensable to its application. For dated references, only the edition cited applies. For undated references, the latest edition of the referenced document (including any amendments) applies.

ISO 7500-1, Metallic materials — Verification of static uniaxial testing machines — part 1: Tension/compression testing machines — Verification and calibration of the force-measuring system

3 Terms and definitions

For the purposes of this document, the following terms and definitions apply.

3.1 elastic modulus

ratio of stress to strain, also known as Young‘s modulus

3.2 bending strength

maximum tensile stress at fracture of a split ring under compression

3.3 split ring

test piece which has the shape of a split ring, prepared by cutting a gap from a ring piece

Cut the ceramic tube into several rings according to the size requirement in 7.1. Then grind and polish the cutting section faces of the ring to a parallelism of 0,02 mm or better. Clean the test pieces with alcohol or pure water, etc. The edges of the test pieces shall be chamfered to avoid edge damage for strength tests. Chamfering is not important for the tests of elastic modulus. Then a slot width about 0,2 r is cut by using a cutting machine for ceramics. II: Material property: test piece is machined from tubes or bulk ceramics, surface shall be ground and polished before cutting into rings. For a given ceramic tube, if surface treatment is in need, the grinding and polishing shall be performed parallel to the tangent direction of the tube first. Cut the ceramic tube into several rings according to the size requirement in 7.1. And then, grind and polish the cutting section faces of the ring to a parallelism of 0,02 mm or better. Clean the test pieces with alcohol or pure water, etc. The edges of the test pieces shall be chamfered to avoid edge damage for strength tests. Chamfering is not important for the tests of elastic modulus. Then a slot width about 0,2 r is cut by using a cutting machine for ceramics. NOTE The aim of polishing is to minimize the damage created in the test pieces due to the preparation process.

ISO 18558:2015 pdf download