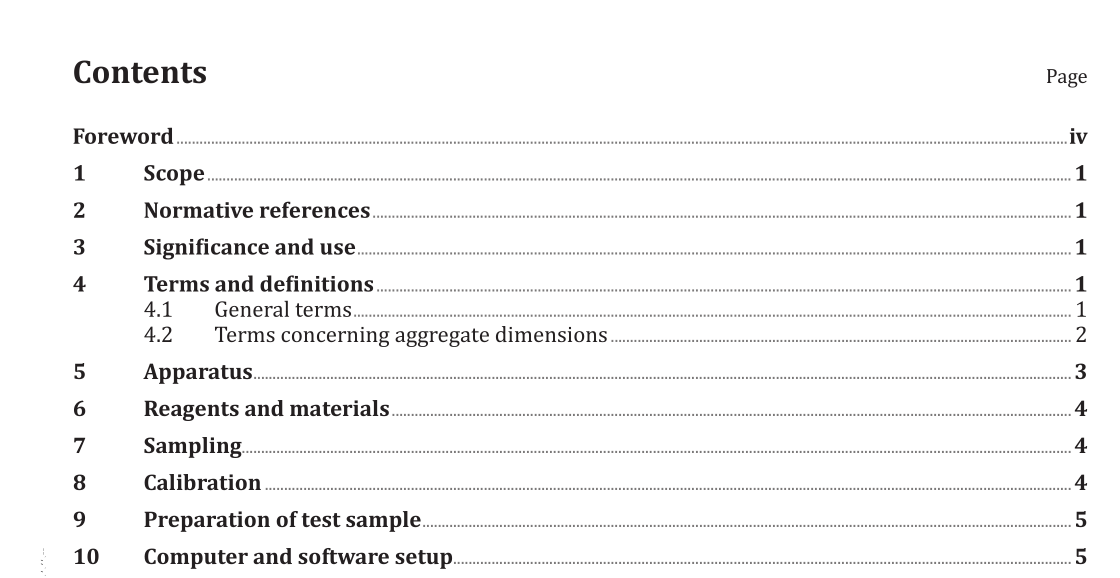

ISO 15825:2015 pdf download.Rubber compounding ingredients — Carbon black — Determination of aggregate size distribution by disc centrifuge photosedimentometry

1 Scope

This International Standard specifies a method for determining the size distribution of carbon black aggregates, using a disc centrifuge photosedimentometer. This technique is based on the hydrodynamic behaviour of carbon black in a centrifugal field. The determination of the aggregate size distribution is important in the evaluation of carbon black used in the rubber industry.

2 Normative references

The following documents, in whole or in part, are normatively referenced in this document and are indispensable for its application. For dated references, only the edition cited applies. For undated references, the latest edition of the referenced document (including any amendments) applies.

ISO 1124, Rubber compounding ingredients — Carbon black shipment sampling procedures

ISO 3696, Water for analytical laboratory use — Specification and test methods

3 Significance and use

Disc centrifuge photosedimentometry produces a rapid mass-differential aggregate size distribution,by continuously measuring the solution turbidity as a function of centrifugation time. In order to obtain a true mass distribution, a light scattering correction has to be applied.

4 Terms and definitions

For the purposes of this document, the following terms and definitions apply.

4.1 General terms

4.1.1 carbon black aggregate

discrete, rigid colloidal entity that is the smallest dispersible unit in a suspension

Note 1 to entry: It is composed of extensively coalesced particles.

4.1.2 spin fluid

inert liquid injected into the disc prior to the sample, through which aggregates sediment

Note 1 to entry: Alkaline conditions minimize agglomeration of dispersed aggregates in most cases.

4.1.3 dispersion fluid

liquid in which aggregates are dispersed

11.7 Inject 0,25 cm 3 of the test sample, prepared as in Clause 9, into the spinning disc, and immediately start the computer for data acquisition. For injecting the test sample, it is recommended to use a syringe with a needle having an inner diameter of 1,19 mm (16 gauge).

11.8 Read the temperature of the chamber measured by the integrated thermocouple.

11.9 Inspect the disc for hydrodynamic instability or streaming, which may be seen as vortices of sample originating from the dark band of layered carbon black, spiralling towards the outer boundary of the spin fluid. A normal run will produce a smooth, diffuse, circular band of carbon black moving outward towards the perimeter of the disc.

11.10 Continue to run until the turbidity has returned close to the baseline, then stop the run. lf the baseline condition is not reached within 1 h, repeat the test with an increased rotational speed. If the baseline condition is not reached within 1 h even though maximum rotational speed (11 000 rpm) is applied, continue the test until the turbidity has returned close to the baseline.

ISO 15825:2015 pdf download