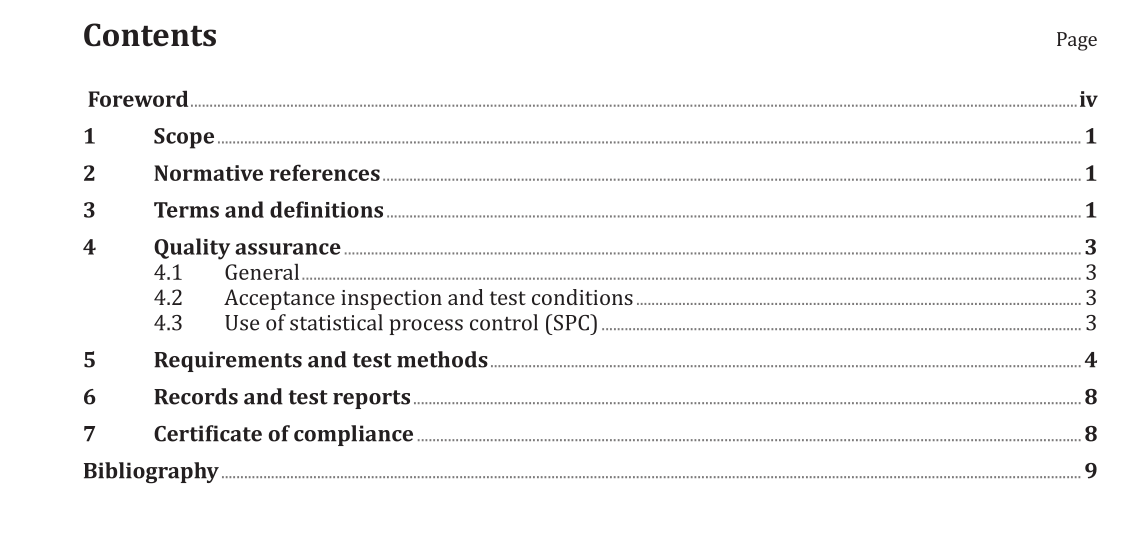

ISO 12289:2016 pdf download.Aerospace — Rivets, solid, in corrosion-resisting steel — Procurement specification

1 Scope

This International Standard specifies the characteristics and quality assurance requirements for solid rivets made in corrosion-resisting steel for aerospace construction.

It is applicable whenever it is referenced in a definition document.

2 Normative references

The following documents, in whole or in part, are normatively referenced in this document and are indispensable for its application. For dated references, only the edition cited applies. For undated references, the latest edition of the referenced document (including any amendments) applies.

ISO 2859–1, Sampling procedures for inspection by attributes — Part 1: Sampling schemes indexed by acceptance quality limit (AQL) for lot-by-lot inspection

ISO 7870–1, Control charts — Part 1: General guidelines

ISO 7870–2, Control charts — Part 2: Shewhart control charts

ISO 7870–3, Control charts — Part 3: Acceptance control charts

ISO 17057, Aerospace — Rivets, solid — Test method

ASTM E112 1) , Standard test methods for determining average grain size

3 Terms and definitions

For the purposes of this document, the following terms and definitions apply.

3.1 batch

quantity of finished products, manufactured using the same processes, from a single material cast (single heat of alloy) having the same definition document (3.4) number, diameter and length code, heat treated together to the same specified condition and produced as one continuous run

3.2 rivet wire sample

length of wire, sampled at one end of the coil used for the manufacture of rivets of the batch (3.1)

Note 1 to entry: The rivet wire samples should undergo the same heat treatments as the rivets of the batch, at the same time.

3.3 rivet sample

rivet sampled at random from the batch (3.1)

4 Quality assurance

4.1 General

The manufacturer shall be capable of continuous production of solid rivets complying with the quality requirements specified in this International Standard. It is recommended that the manufacturer be certified to a recognized quality management system. The certification authority may be the prime contractor. The purpose of acceptance inspection and tests of a solid rivet is to check, as simply as possible, using a method which is inexpensive but the most representative of the actual conditions of use, with the uncertainty inherent in statistical sampling, that the solid rivets satisfy the requirements of this International Standard. Acceptance inspections and tests shall be carried out by the manufacturer, or under his responsibility.

4.2 Acceptance inspection and test conditions

Acceptance inspections and tests (requirements, methods, and numbers of solid rivets) are specified in Table 1. They shall be carried out on each batch. Solid rivets shall be selected from the batch to be tested by simple random sampling. Each solid rivet may be submitted to several inspections or tests, provided that none of characteristics to be verified has been previously altered during any of these inspections or tests. The solid rivets to be subjected to destructive inspections or tests may be those on which non- destructive inspections or tests have been carried out. A batch declared unacceptable after the acceptance inspection shall be resubmitted for acceptance only after all the defective units have been removed and/or defects have been corrected. In this case, the attribute(s) which caused the rejection shall be verified using a sample of twice the normal size with the same acceptable limit. If the reason for rejection results from the method, the test apparatus or from faulty heat treatment which can be rectified in a satisfactory manner, the tests may be repeated after elimination of the cause, provided that any surface treatment be removed prior to heat treatment, wit

ISO 12289:2016 pdf download