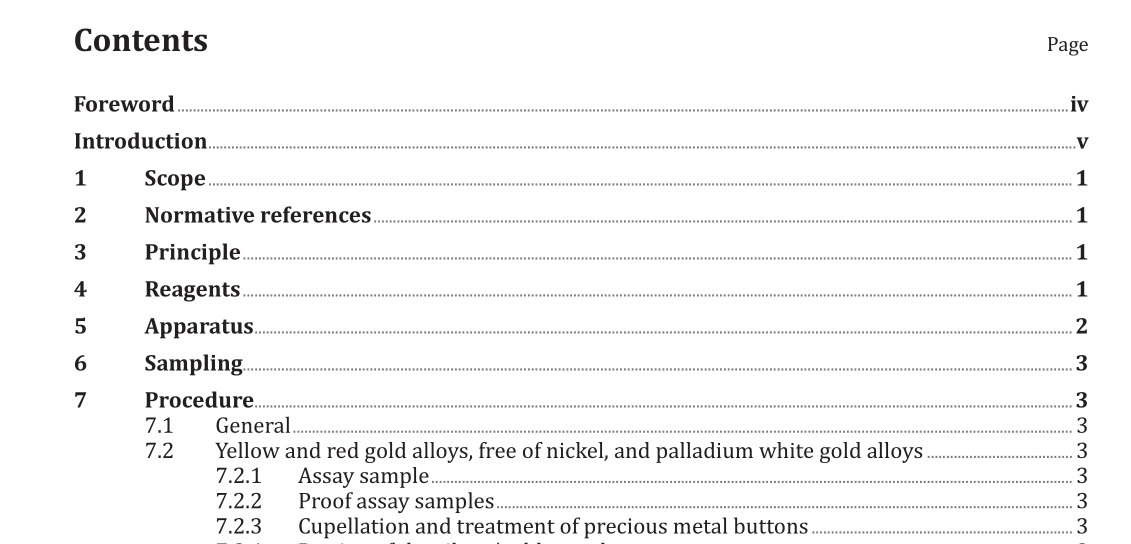

ISO 11426:2014 pdf download.Jewellery — Determination of gold in gold jewellery alloys — Cupellation method (fire assay)

1 Scope

This International Standard specifies a cupellation method (fire assay) for the determination of gold in gold jewellery alloys. The gold content of the alloys should preferably lie between 333 and 999 parts per thousand (‰). The procedure is applicable specifically to gold alloys incorporating silver, copper, and zinc. Some modifications are indicated where nickel and/or palladium are present in the so-called white gold alloys, as well as for alloys containing 990 or more parts per thousand (‰) of gold. This International Standard is intended to be used as the recommended method for the determination of fineness in alloys covered by ISO 9202.

2 Normative references

The following documents, in whole or in part, are normatively referenced in this document and are indispensable for its application. For dated references, only the edition cited applies. For undated references, the latest edition of the referenced document (including any amendments) applies.

ISO 11596, Jewellery — Sampling of precious metal alloys for and in jewellery and associated products

3 Principle

The gold alloys are inquarted with silver, compounded with lead, and cupelled in a cupellation furnace until a precious metal button is obtained. After flattening and rolling, the silver is extracted (parted) in nitric acid and the gold weighed. Possible systematic errors in the procedure are eliminated by assaying standard proof samples in parallel. NOTE Inquartation is the addition of silver to gold alloys in a specific ratio in order to enable the parting of gold from silver by means of nitric acid.

7.2.3 Cupellation and treatment of precious metal buttons

Place the assay and the proof assay samples (7.2.2), tightly wrapped in lead foil, on magnesia cupels (5.3), which have been preheated to at least 1 000 °C in the cupellation furnace (5.2). Place the cupels with the proof assay samples as close as possible to the corresponding assay samples in the cupellation furnace maintained at 1 050 °C to 1 150 °C. Continue heating (about 25 min) under oxidizing conditions until the cupellation process is completed. Remove the cupels from the furnace. Allow the precious metal buttons to cool down before lifting them from the cupels with the assay pliers (5.7). Squeeze the buttons and brush their undersides carefully with a brush (5.13) to remove any adhering cupel material. Flatten the beads on the polished anvil (5.8) with a polished hammer (5.9) and anneal by heating just to red heat. Roll them into 0,12 mm to 0,15 mm thick strips and anneal again. Roll the strips into cornets without contamination or loss of gold. The cupel should be examined carefully to ensure that the precious metal bead contains all gold of the sample. If small droplet residues are present, a full assay has to be repeated.

ISO 11426:2014 pdf download