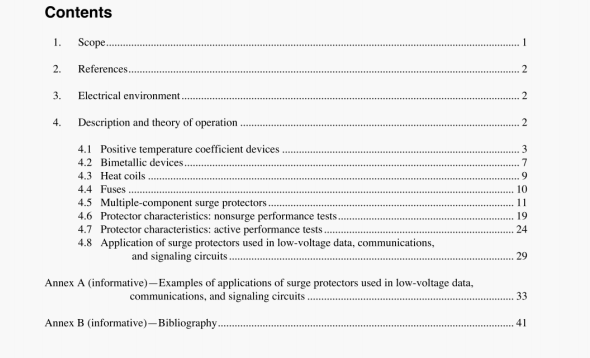

IEEE Std C62.43:1999 pdf free download.IEEE Guide for the Application of Surge Protectors Used in Low-Voltage (Equal to or Less than 1000 V, rms or 1200 Vdc) Data, Communications, and Signaling Circuits.

Those applications requiring multiple FTC devices sometimes also require a certain similarity in FTC device resistance (i.e.. balance), so as to reduce the amount of noise generated in the equipment in the presence of common-mode signals, such as those induced by ac power lines. A large FTC resistance imbalance may result in a significant and undesirable potential difference across the equipment. which can interfere with the equipment’s normal operation.

FTC devices are typically used in combination with overvoltage protection devices to protect equipment against those overcurrents that do not activate the overvoltage devices. (These low-voltage overcurrcnts are sometimes called sneak currents.) The overvoltage protection devices are usually located in the circuit between the PTC devices and the source of the surge. In that position. they protect the load from overvoltages and also limit surges to less than the rated voltage of the PTC devices for surges that last long enough to operate the FTC devices.

Finally, since FTC devices arc usually placed in series with the load, they introduce signal loss into the circuit. If their resistance is too high compared to the load resistance, this loss may become unacceptable.

4.2 Bimetallic devices

4.2.1 Description

A protection device using a bimetallic sensing element can be activated by current, temperature. or a combination of both. The device is placed in series or in parallel with the line. The contacts allow current to how to the equipment until excess current or external temperatures heat the bimetallic sensing clement to the trip point. This activates the contact and opens. or grounds. the line, removing power from the equipment. As the bimetal cools down, automatic reset occurs when the temperature reaches the reset point. Manual reset can be achieved through mechanical means.

4.2.2 Theory of operation

The sensing element of a binallic device consists of a composite material made up of Iwo or more metallic layers with different coefficients of thernial expansion. When subjected to an increase in temperature. the high expansion side will be tinder compression while the low expansion side is under tension. These forces produce a moment that causes the element to bend. This action, which, based on the design. can be a creep action or a snap-action device, opens or closes a contact that controls current flow. Creep-action devices. which have a slow make or break, are generally acceptable for low-voltage (< 24V) applications while snap- action devices can be used up to 100 V and 250 A. Heating of the bimetallic element can be achieved by an external heat source as well as through ohmic heating.

IEEE Std C62.43:1999 pdf free download