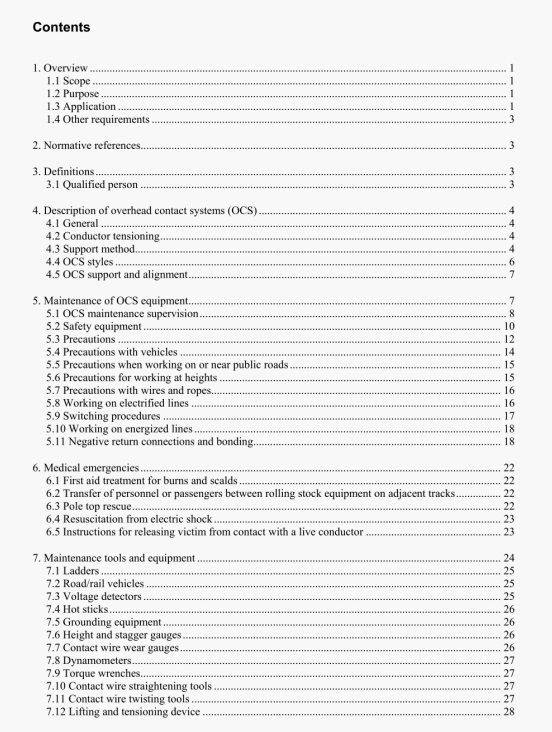

IEEE Std 1628:2009 pdf free download.IEEE Recommended Practice for Maintenance of DC Overhead Contact Systems for Transit Systems.

4.5 OCS support and alignment

The essence of good OCS design and maintenance is to ensure that the wires are arranged and maintained above the track in such a way that thc pantograph or trolley pole shoe vill ride undcr the contact or trolley wire at all times, in all climatic conditions, and with proper alignment. To achieve this, the OCS conductors must be supported and located (registered) accurately in relation to the current collector mounted on top of the transit vehicle.

The type of conductor support arrangement for the OCS is, to some extent, dependent upon the tensioning method that has been selected. With an AT system, hinged cantilever construction or cross spans with support pulleys or pendulum hangers are used to accommodate the along-track movement of the conductors due to temperature changes.

For FT systems, where there is no along-track movement, the support arrangements can be simpler. Rigid bracket arms are often selected and cross span supports usually offer direct suspension of the conductor support clamps and insulators. Hinged cantilevers arc also often used to facilitate construction, rather than to satisfS’ system requirements.

The OCS for streetcars equipped with trolley poles and ETls should optimally be configured with tangent wires and should be located right over the streetcar or ET[3 path. In curves, the trolley wire is usually offset toward the center of the curve to improve tracking of the trolley pole shoe. The OCS layout in intersections should be established based on the location of switches, curves, and other special overhead assemblies with due consideration for permissible traffic movements and allowable speeds. The layout should be finalized during construction by having a pole-equipped vehicle traverse through the intersection to ensure there are no conflicts.

Structures used to support the cantilevers, bracket arms, headspans and cross-spans have included I-I- section steel poles, fabricated double channel or four angle structures (galvanized or painted), and tapered tubular concrete poles. Many of the recent modem LRT systems have utilized bolted base, tapered tubular steel poles, with limited use of parallel-sided square or rectangular steel tubes. Also used are parallel-sided. stepped tubular steel poles and wood poles. though wood poles are subject to significant, non-consistent bending and the need for lateral, across-track back-guying to sustain the loading. Headspan and cross-span or portal structures, in many different configurations, have been employed to support multiple OCS assemblies in multi-track areas, where it was not possible to locate individual poles between tracks. The OCS has also been supported by direct attachments to buildings, overpass bridge structures, and tunnels.

IEEE Std 1628:2009 pdf free download