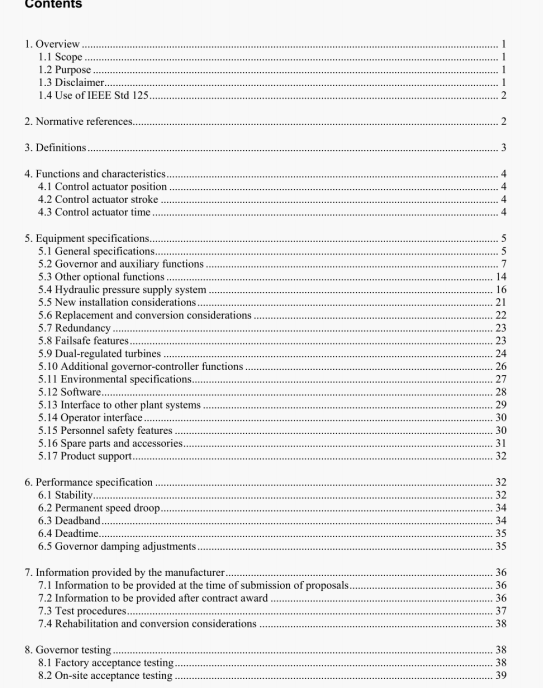

IEEE 125:2007 pdf free download.IEEE Recommended Practicefor Preparation of Equipment

Specifications for Speed-Governing of Hydraulic Turbines Intended to Drive Electric Generators.

5.2.5 Control actuator limit

‘The governor-control systen should provide a means of limiting the maximum allowable position of’ the turbine-control actuators, which should be adjustable from ,ero to full control actuator stroke. The control actuator limit should also be adjustable (mm a remote location. The provision of an adjustable minimum control actuator position limit may also be specified. The minimum control actuator position limit may be activated or dc-activated under cenain specified operating conditions such as overspeed. operating with the unit circuit breaker open or while in synchronous condenser mode.

5.2.6 Control actuator velocity or time adjustment

A control actuator velocity adjustment should be provided. Ikith the maximum opening and closing velocities of the turbine-control actuator should be independently adjustable. Typically, these maximum velocities are expressed in control actuator full stroke operating times. The method of operation should be such that operation of any control, automatic device, or auxiliary device should be able to muse the turbine- control actuatur at a velocity no greater than that set by these adjustments. The method of adjustment should be specified and should be secure, thereby minimizing the chance of accidental misadjustmcni Typical methods include adjustable distributing valve stop nuts. tiow restricting orifices and flow control valves.

The opening and closing travel times should be specified and are normally dictated by the permissible water-hammer effect in the water conduit and the permissible ovempeed following load rejection. The closing time may also be dictated by the possibility of drañ tube water column separation, The opening lime may also be dictated by the possibility of surge tank (or swge shaft) air entrainment,

5.2.7 Control actuator position feedback

Control actuator position feedback is a basic requirement of a speed-governing system. The position feedback system is used to transmit the position of the turbine-control actuators to the governor-control system. The response time of the position feedback system should be compatible with the governor peiforniance requirements as specified in Clause 6. The accuracy and resolution of the position feedback system should be specified and should be guaranteed over the operating temperature range specified in 5.11.1. Values of O.l for accuracy and 0.02% for resolution have been tbund through experience so provide acccptablc pertbrmancc.

The position feedback system should be designed such that any failure in the mechanism will cause the turbine-control actuators to rcspond in the manner specified for example, force the turbine-control dcvicc so fully close).

5.2.8 Speed-sensing source

Speed sensing is a basic requiremern of a speed-governing sysieni The range and response time of the speed-sensing source should be compatible with the governor performance requirements (as specified in Clausc 6) and as required for the adjustment range of the speed switches. The accuracy and resolution of the speed-sensing source should be specified and should be guaranteed over the operating temperature range specified in 5.11.1. Values of 0.03% for accuracy and 0.003% for resolution have been found through experience so provide acceptable performance.

IEEE 125:2007 pdf free download