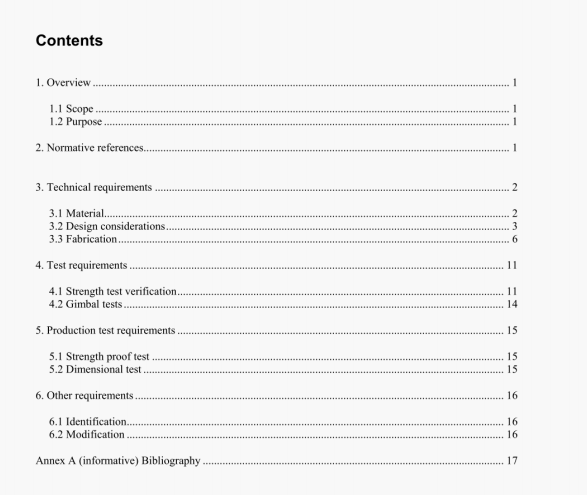

IEEE 1070:2006 pdf free download.IEEE Guide for the Design and Testing of Transmission Modular Restoration Structure Components.

3.2.4 Gimbal design and tolerance

For gimbals, basic design and all manufacturing tolerances should be as specified in Figure 3.

3.2.5 Foundation base design and tolerance

For foundation bases, basic design and all manufacturing tolerances should be as specified in Figure 4.

3.2.6 Box section design and tolerance

For box sections, basic desigii and all manufacturing tolerances should be as specified in Figure 5.

3.2.7 Workmanship

All work should be performed using the best modern practices of the industry. Material should be as specified in 3.1 (new and free of defects or irregularities). All components of the same design and designation should be identical: like components should be interchangeable. All corners should be rounded and sharp edges should be broken.

3.3 Fabrication

Fabrication should not begin unil the purchaser has approved drawings. The best modern practices should be used in the manufacture and fabrication of the types of materials covered in this guide.

3.3.1 BendIng

All bending should maintain sufficient thickness of material in order to provide full strength without impairing the material.

3.3.2 Cutting

Cutting of plates and structural shapes should be guided by electrical or mechanical means to assure a neat, accurate cut. Cuts should be clean and free from sharp edges.

3.3.3 Drilling and milling

All load-bearing holes should be drilled, and all slots should be milled in all material thicknesses, Punching of holes or slots is not recommended.

3.3.4 Welding procedures

Welding procedures should be in accordance with American Welding Society’s Aluminum Sirudural Code. All welds should completely seal. There should be no voids or seams between joining surfaces into which fluids may enter Welders and welding operators should be qualified in accordance with ANS/AWS Dl.2.

4.1.5 Ultimate strength bending-bolts

Using production bolts and nuts, a 6.4 m column section should be bolted to a suitable test structure on oneend of the column (identical to Figure 7 except with the loads specified in the following sentences in thisparagraph).A load should be applied at a rate not to exceed 8.9 kN/min. The combined assembly ofcolumn, bolts, and nuts should have an ultimate strength greater than an equivalent moment of 190 oooNm. The first component to fail should be the bolt and nut assemblies. The welded column should not bethe first to fail; however, secondary failure of the welds after a bolt failure is permissible.

4.1.6 Ultimate strength bending-welds

Using extra high strength bolts and nuts, a 6.4 m column section should be bolted to a suitable test structureon one end of the column (identical to Figure 7 except with the loads specified in the following sentences inthis paragraph). Four tests should be performed by rotating the column. A load should be applied at a ratenot to exceed 8.9 kN/min unless failure occurs. In no case should the column have an ultimate strength lessthan an equivalent moment of 190 000 Nm.

IEEE 1070:2006 pdf free download