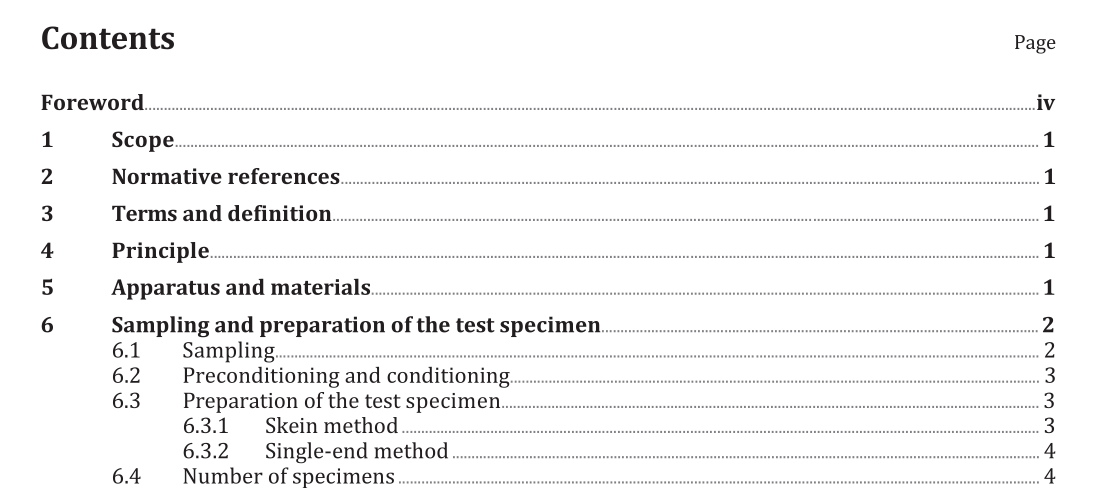

BS ISO 18067:2015 pdf download.Textiles — Synthetic filament yarns — Determination of shrinkage in dry-hot air (after treatment)

1 Scope

This International Standard specifies methods for the determination of dry-hot air shrinkage (after treatment) of synthetic filament yarns, skein method and single-end method. The skein method provides two forms of measurement which are of manual and automatic types. The single-end method gives the result by manual measurement.

In case of dispute, manual measurement procedure is to be used.

If these methods are not applicable, the corresponding test methods may be agreed between interested parties.

This International Standard is applicable to synthetic filament yarns of linear density less than 3 000 dtex.

This International Standard is not applicable to partially oriented yarns.

2 Normative references

The following documents, in whole or in part, are normatively referenced in this document and are indispensable for its application. For dated references, only the edition cited applies. For undated references, the latest edition of the referenced document (including any amendments) applies.

ISO 139, Textiles — Standard atmospheres for conditioning and testing

3 Terms and definition

For the purposes of this document, the following terms and definitions apply.

3.1 shrinkage in dry-hot air (after treatment)

decrease in length of a specimen as a result of thermal treatment in dry-hot air, expressed as a percentage of its original length, which measured under tension before and after treatment

4 Principle

Under specific condition, a test specimen is treated in dry-hot air. Shrinkage is calculated as variation in length, measured before and after treatment.

5 Apparatus and materials

5.1 Skein winding reel, which meets the following requirements:

a) 1 000 ± 2,5 mm reel circumference, driven either automatically or manually;

b) a traversing mechanism to avert overlapping when several skeins are wound at the same time;

c) a tensioning device to maintain tension within the recommended limits, accurate to within ± 10 %;

d) a device to count reel revolutions, preferably capable to stop winding automatically and warn when nearing the specified number of reel revolutions;

e) a mechanism to reduce the reel circumference for easy removal of the skein.

5.2 Length-measuring stand, which meets the following requirements:

a) a stand for measuring specimen length of least 1 mm gauge length;

b) a millimetre scale to determine specimen length, accurate to within ±1 mm;

c) a steel hook or a clamp, where the top of the hook or the lower side of the clamp (where the specimen hung from) is positioned in line with the zero index of the scale;

d) tensioning weights with hooks or clamps for applying tensile force to specimens, accurate to within ±10 %.

5.3 Automatic shrinkage tester, which meets the following requirements:

a) automatically applies specified tension, measures specimen length, and calculates the shrinkage based on length values;

b) 0,05 mm resolution of length measurement;.

c) a specimen holder for suspending specimens more than 600 mm high, which can consistently hold 2,5 cN load per skein for the duration of the testing procedure with several skeins arranged and tested in succession.

BS ISO 18067:2015 pdf download