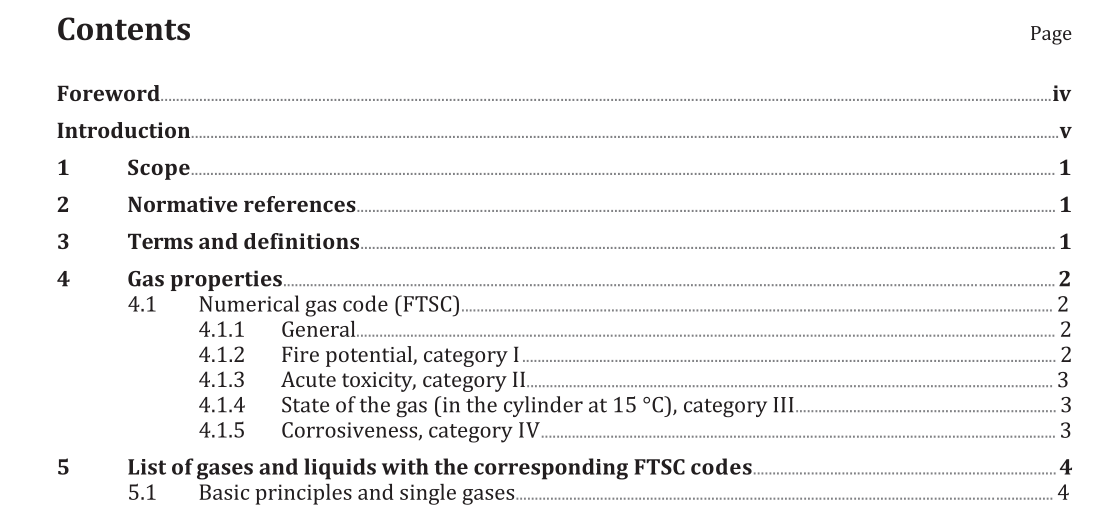

BS ISO 14456:2015 pdf download.Gas cylinders — Gas properties and associated classification (FTSC) codes

1 Scope

This International Standard gives a list of FTSC (fire potential, i.e. “oxidizing potential and flammability”,toxicity, state of the gas, and corrosiveness) codes determined according to the relevant properties of gases and of some liquids that are transported under pressure.

It does not cover gas material compatibility which is covered by ISO 11114 (all parts).

2 Normative references

The following documents, in whole or in part, are normatively referenced in this document and are indispensable for its application. For dated references, only the edition cited applies. For undated references, the latest edition of the referenced document (including any amendments) applies.

ISO 10156, Gases and gas mixtures — Determination of fire potential and oxidizing ability for the selection of cylinder valve outlets

ISO 10298, Determination of toxicity of a gas or gas mixture

ISO 10286:2015, Gas cylinders — Terminology

3 Terms and definitions

For the purposes of this document, the following terms and definitions apply.

3.1 gas mixture

combination of different single gases deliberately mixed in specified proportions

[SOURCE: ISO 10286:2015, definition 704]

3.2 liquefied gas

gas, which, when packaged for transport, is partially liquid (or solid) at temperature above −50 °C

[SOURCE: ISO 10286:2015, definition 706]

3.3 compressed gas

gas, which, when packaged under pressure for transport, is entirely gaseous at −50 °C

Note 1 to entry: This category includes all gases with a critical temperature less than or equal to −50 °C.[SOURCE: ISO 10286:2015, definition 705]

NOTE 1 Subdivisions 5 and 6 have been adopted as a result of a compromise between the European and the North American approach. The European preference for a limit of 250 bar reflects the current tendency towards higher pressure applications. The current North American practice requires a limit of 207 bar for which their pressure reducing valves are designed. This is the working pressure at the referenced temperature of 15 °C. Therefore, three pressure classes have been retained. Other jurisdictions might use different values. Either subdivision 5 or subdivision 6 shall be used, never both. The selection of either subdivision will determine the applicable pressure for subdivision 7. Subdivision 5 or 6: medium pressure range, each user being required to select one subdivision exclusively to determine the upper limit of the medium pressure range (i.e. 182 bar or 250 bar). Subdivision 7: high pressure range, the lower limit (182 bar or 250 bar) of which depends on the subdivision selected for the medium pressure range. After the introduction of subdivisions 5, 6, and 7, a number of pressure ranges have been (or are being) established to make the selection of the proper cylinder valve outlet connection (e.g. 500 bar, 800 bar, sub atmospheric pressure. These ranges have been chosen to protect downstream regulators and other ancillary equipment from over-pressurized conditions. Consequently, for the tables in 5.3, the third digit (S) used for all compressed gases is “5” to indicate that this is a compressed gas. NOTE 2 Subdivisions 8 and 9 have been allocated for liquid withdrawal cylinders of cryogenic gases in the USA.

BS ISO 14456:2015 pdf download