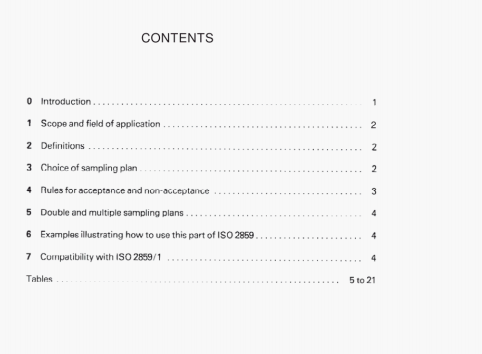

AS 1199.2:2003 pdf – Sampling procedures for inspection by attributes Part 2: Sampling plans indexed by limiting quality (LQ) for isolated lot inspection.

5 Double and multiple sampling plans

Tables 4 provide me sample stzes and acr’eptance oatterns for the double and multiple sanipliny plans in ISO 29/1 cquivolcnt to tho anglo oampling piano givon in tables P1 to RiO Tha sample size code agrees with that in ISO ?PM11 and the acceptance pattern code I. the acceptance number in the corresponding single aize plans Since procedure A and pro c,dure B plans have similar OC curves for non-zero acc.ptance numbers, these double and muLtiple plans can also be used In procedure A to replace the corresponding single sampring plan. The user is referred to 111.2 and 11.1.3 in ISO 2859/i for the operation of these double and multiple sampling plans.

6 Examplas illustrating how to use this part of ISO 2S59

6.1 A consumer wishes to purchase prepecked sets of 10 screws to Include In the sell-assembly bookcase kits he plans to sell, While he prefers each set to contain exectly 10 screws, he can tolerate 1 % of packs with fewsi’ screws but he does not want to nsk accepting a much higher percentage of detclent packs. He plans to produce 5 000 kits in lots of 1 250.

The supplier agrees to use procedure A with nominal limiting quality 3,15 For lots of size 1 250, the selected pldn has ii — 125, Ac — 1.

The supofler offers to provide the packs needed for all 5 000 kits as a &ngle lot, The new sampling plan has a – 250, Ac – 3,

The smgle lot requires proportionately fewer tested items and yet the sampling plan still provides a high probability of reiection for quality as poor as 3,15 %. 4i!e increasing the probaMity of acceptance tot a In? of nilafrey 1 % trnrn O,b4 to 0,.

6.2 The same consumer wishes to purchase the wooden corvonents of his self-assembly bookcase kit as standard-size, plastic-faced chipboard panels. The supplier produces these panels as part of his regular production and regards the 7 S00 panels needed for each lot of I 250 kits as single lots In the general stream of supply to DIV shops. Scars to the plast.c facing occur with probabIlity 0,025 according to quality control checks. The consumer can tolerate some scarred panels since Utese cdii be detected dud set aside duriny the prucesailiy to produce the bookcase kit, but he decides that if 5 % of the panels were scarred this would present problems during the processing.

The consumer and supplier agree that procedure B is appropriat and select nominal limiting quality 5,0 % with inspection level 5-4. With this plan the probability of acceptance with the current process. A lot which is unacceptable has to be 100 % inspected before use and this high probability of non-acceptance implies inspection costs larger than desirable.

Inspection level III would have provided a sampling plan with n = 315 and Ac — 10. The current process average would produce lots with a probability of acceptance greater than 0,80. A supplier with a better process dveraye, say 1 %, would obtain a similar probability of acceptance with inspection level S-4. This illustrates the ability of better to work with smaller sample sizes whilst still meeting the same limiting quality criterion.

AS 1199.2:2003 pdf – Sampling procedures for inspection by attributes Part 2: Sampling plans indexed by limiting quality (LQ) for isolated lot inspection