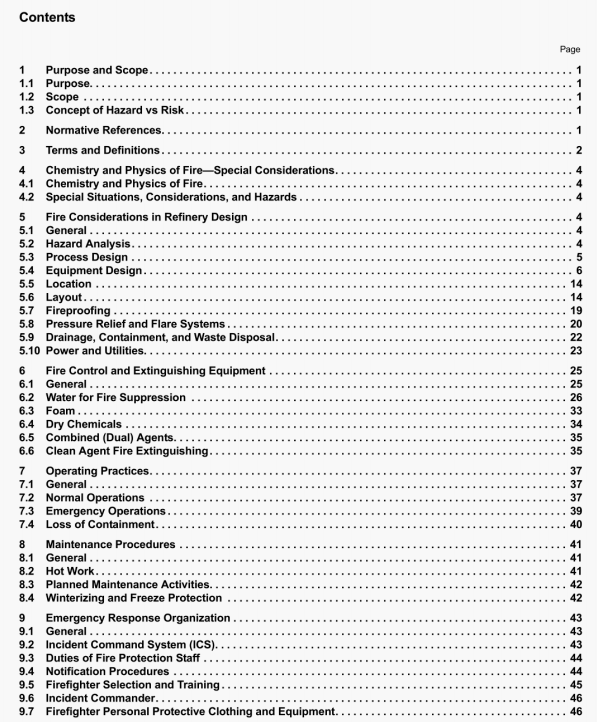

API RP 2001:2012 pdf download.Fire Protection in Refineries.

5.4.3.2.2 Internal Design

Internal design & vessels should avoid pockets where the lack of drainage would allow water (or hydrocarbons) to aocumulate, particxiarty during start-up. Proper placement of vent piping can avoid bypassing and allow effective purging of otherwise trapped condensable gases, wtich could leave water or light hydrocarbons in equipment The sudden generation of steam caused by the contact of hot-oil charge stocks with water can result in dangerous overpressure of equipment. Hydrocarbons retained in equipment can create future fire (or indusffial hygiene) concerns.

5.4.3.2.3 Protection of Vessels

Vessels with internal refractory or insulation, or vessels that handle matenals entirely in the vapor phase. may be subject to r,id overheating and rupture when exposed to fire if passive fireproofing, active fire protection cooling, insulation, and/or a vessel depressunng system is not provided Other vessels (including those with two phases or tanks containing flammable liquids) may also be subject to overheating (We protection cooling or adequate distance separation is not provided

5.4.3.2.4 Flanges

Vessel connections should be flanged as close to the vessel as practical to permit isolation. During the design and installation stages, consideration should be given to access to the flanges for blinding. Valves should be strategically located to allow opening of flanges for the purpose of installing and removing isolation blinds.

5.4.3.3 Block Valves

Where Large volumes of flammable liquid are contained in process vessels, where feasible, block valves should be installed on connections below the liquid level, This will permit shutoff of fuel flow if downstream piping or equipment become involved in a fire. These manual or remote valves should be considered a prudent “second line of protectio& with the first being prevention through design and operations.

5.4.3.4 IsolatIon Valves

5.4.3.4.1 General

A key consideration for isolation valves is being able to isolate sections of process to minimize the quantity of hydrocarbons released and prevent influx of additional material from other areas. Isolation valves should be provided at unit boundaries or within process unit areas to isolate equipment during fire situations. Consideration should be given to safe access and the ability to physically operate manually operated valves during fire conditions or in emergency situations. Where possible. battery limit valves should be spaced sufficientty far from process eqelpment fire hazardous areas to allow safe manual actuation. If located inside fire hazard areas, valves may need to be capable of remote operation.

Isolation valves can also permit blwiding for maintenance and inspection. During blinding operations, blinds suitable for equipment-rated pressure should be installed Isolation valves and drains should be provided for equipment that may be opened or removed during repair operatiOns. See API 553.

API RP 2001:2012 pdf download