UL 1063:2017 free download Machine-Tool Wires and Cables

6.3 Number and assembly of strands and conductor diameters

6.3.1 Conductors shall be stranded with at least the number of strands indicated in the applicable Table 6.5, 6.6, or 6.7. A 1 9-wire combination round-wire unilay-stranded soft-annealed copper conductor shall be round and shall consist of a straight central wire, an inner layer of six wires of the same diameter as the central wire with the six wires having identical lengths of lay, and an outer layer consisting of six wires of the same diameter as the central wire alternated with six smaller wires having a diameter of 0.732 times the diameter of the central wire and with all twelve wires of the outer layer having the same length of lay and direction of lay as the six wires of the inner layer. Otherwise, no particular assembly of the individual strands is required; however, untwisted strands shall not be used for the entire conductor or any part thereof. Class B or C 16 AWG – 1000 kcmil conductors shall be with or without compressed strands. Compressed stranding shall not be used in the Size 22-7 or in the Class K and M constructions. Otherwise, any stranding other than single-bunch, bunch stranding and the concentric, rope-lay, and 19-wire combination unilay assemblies indicated in Tables 6.5, 6.6, and 6.7 shall not be used unless the results of an evaluation demonstrate that the stranding is appropriate for the application. Compact stranding shall not be used.

6.3.2 A compressed round concentric-lay-stranded conductor shall be a round conductor consisting of a central core wire surrounded by one or more layers of helically laid wires with, for the 6 AWG – 1000 kcmil sizes, the direction of lay reversed in successive layers or unilay or unidirectional lay. The direction of lay of the outer layer shall be left-hand in all cases. The strands of one or more layers shall be slightly compressed by rolling, drawing, or other means to slightly change the originally round strands to various shapes that fill some of the spaces originally present between the strands.

6.3.3 A finished compressed-stranded Class B or C conductor shall not be larger in average diameter than the maximum diameter indicated for the size under Y in Table 6.5 and shall not be smaller in average diameter than the minimum diameter indicated for the size under Z in Table 6.5 Class B or C 16 AWG – 1000 kcmil conductors with uncompressed strands shall not be larger or smaller in average diameter than the maximum and minimum diameters indicated for the size in Tables 20.4 (Class B) and 20.4.1 (Class C) of UL 1 581. The average diameter of the conductor is to be determined and compared with the table in the manner described in 6.3.4 and 6.3.5. Class B 1 AWG – 1000 kcmil conductors with round unilay or unidirectional lay compressed strands shall not be larger or smaller in average diameter than the maximum and minimum diameters indicated for the size in Table 20.3.1 of UL 1581. A finished 19-wire combination unilay conductor shall not be larger in average diameter than the maximum diameter indicated for the size in Table 20.6 of UL 1581. The average diameter of a conductor is to be determined and compared with the tables in the manner described in 6.3.4 and 6.3.5.

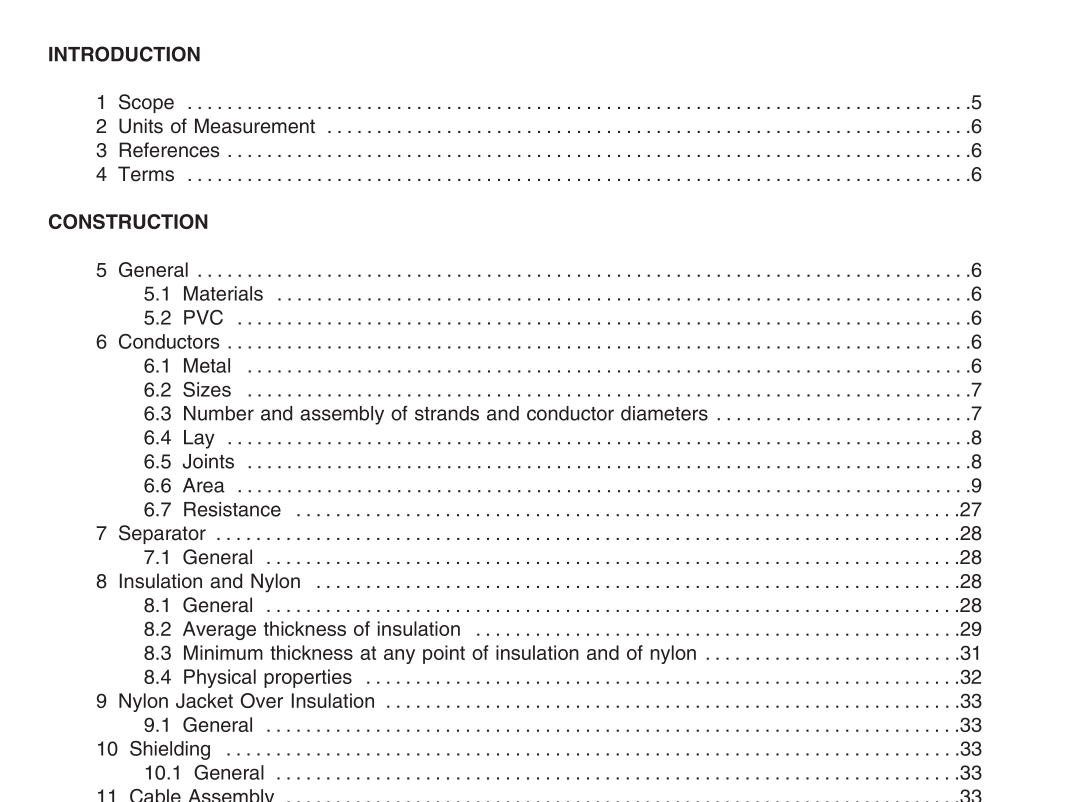

6.3.4 For diameter measurements, the insulation is to be removed at a single place at the center of a straight length of the finished conductor. Measurements of the conductor diameter are to be made over the metal-coated or uncoated conductor strands by means of a machinist’s micrometer caliper having flat surfaces both on the anvil and on the end of the spindle. The measurements for all constructions for which the diameter requirements apply are to be made over the strands rather than across flats; this is illustrated in Figure 6.1 only for a 7-strand construction. The measurements are to be made on a line extending through the center of the conductor and through the center of two wires (strands) in the outer layer that are 180° apart. The micrometer is to be calibrated to read directly to at least 0.001 inch or 0.01 mm, with

UL 1063:2017 free download