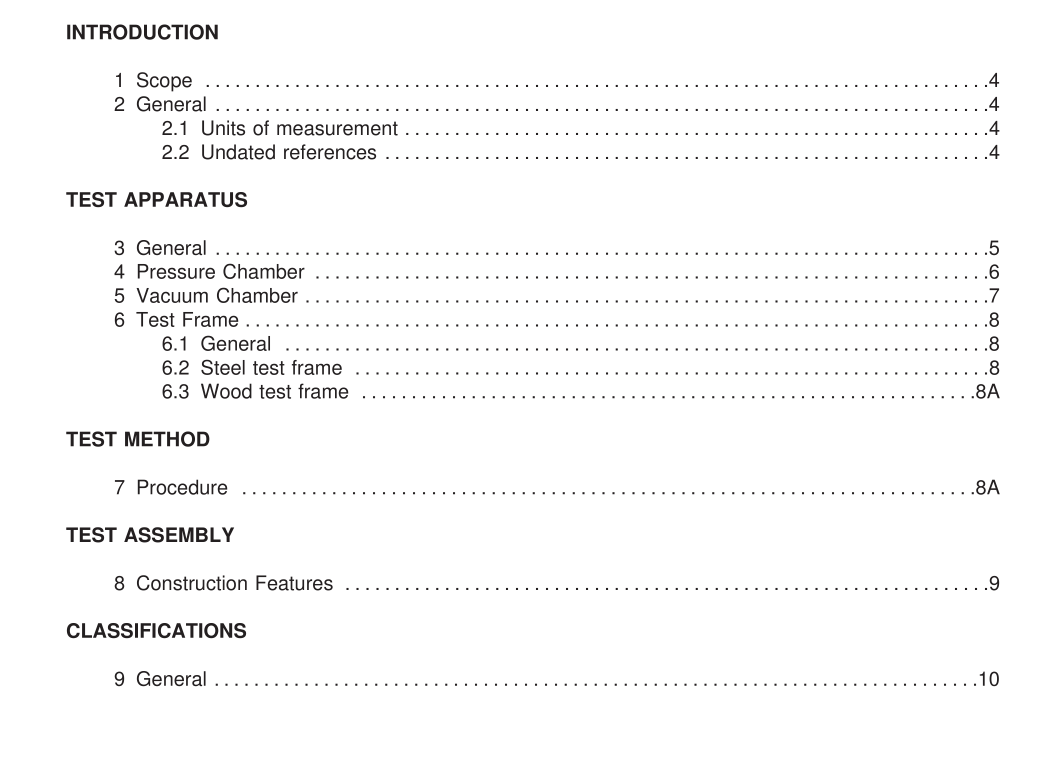

UL 580:2013 free download Tests for Uplift Resistance of Roof Assemblies

1 Scope

1.1 The method of test specified in this standard is intended to determine the uplift resistance of roofassemblies consisting of the roof deck and roof covering materials. It is applicable to any type of roofassembly which is adaptable to the test equipment. Tests to evaluate other potential hazards of roofassemblies are not within the scope of these requirements.

1.2 The purpose of this test is to evaluate the comparative resistance of roof assemblies to positive andnegative pressures.

1.3 The test evaluates the roof deck, its attachment to supports, and roof covering materials. It does notevaluate roofs adjacent to chimneys,overhanging eaves, or similar construction,connections of theassembly to main structural supports(girders, columns,or other supports),structural integrity ofsecondary supports (purlins, joists, bulb tees, or the like), or deterioration of roofing materials.

1.4 Deleted July 9,2009

2 General

2.1 Units of measurement

2.1.1 lf a value for measurement is followed by a value in other units in parentheses, the first stated valueis the requirement.

2.2 Undated references

2.2.1 Any undated reference to a code or standard shall be interpreted as referring to the latest editionof that code or standard.

3 General

3.1 The test apparatus is to consist of three sections which include a top section to create a uniform vacuum, a center section in which the roof assembly is constructed, and a bottom section to create a uniform positive pressure. See Figure 3.1 . Each section is to be sealed to maintain the specified pressures.

3.2 The inside dimensions of the test apparatus are to be a minimum of 1 0 by 1 0 feet (3.05 by 3.05 m).

3.3 The test chamber is to be capable of applying steady positive pressures on the underside of the test assembly and both steady and oscillating negative pressures, as specified, upon the top surface.

3.4 Recording equipment is to be used to make a permanent record of the pressure levels developed in the test as a function of time.

3.5 Sections 4 – 6 contain a specification of the presently used test apparatus. Design modifications shall not be made unless the test results are equivalent to the results obtained from the specified apparatus.

4 Pressure Chamber

4.1 The pressure chamber is to be formed from C12 x 30 channels and is to measure a minimum of 10by 10 feet (3.05 by 3.05 m) by 9 inches (229 mm) deep.A 4-1/2 inch (114 mm) wide by 1/4 inch (6.4 mm)thick steel plate is to be welded around the top of the chamber.

4.1 revised July 9, 2009

4.2 The floor of the pressure chamber is to be fabricated from 1/8 inch (3.2 mm) thick sheet steel, weldedat the seams and supported by five 3-by 7.5-inch (76- by 190-mm) steel shapes. The chamber is to besupported by an MC8 x 20 channel at each side and a w8 x 28 beam at each corner.

4.3 Several windows constructed of break-resistant glazing material are to be installed in the chamberwalls to allow observation of the underside of the test assembly.

4.4 Flood lights are to be mounted in the chamber for illumination of the under surface of the testassembly.

4.5 Air is to be admitted into the chamber through a 6-by 6-inch (152- by 152-mm) opening cut into thebottom of the chamber.

4.6 A steel baffle is to be placed over the air inlet opening for even distribution of air pressure.The baffleconsists of two vanes with the lower vane measuring 22 by 22 inches (559 by 559 mm) and the uppervane measuring 16 by 16 inches (406 by 406 mm).The vanes are set at an angle of 30 degrees from thehorizontal.

4.7 Air is to be provided by a blower attached to a 3 horsepower (2.2 kW output) electric motor that iscapable of delivering 862 cubic feet (24.4 m3) of air per minute at a static pressure of 11 inches (2739 Pa)of water.

4.8 The pressure blower starter controls are to be located on the side of the chamber for ease of accessand rapid shut down.

UL 580:2013 free download