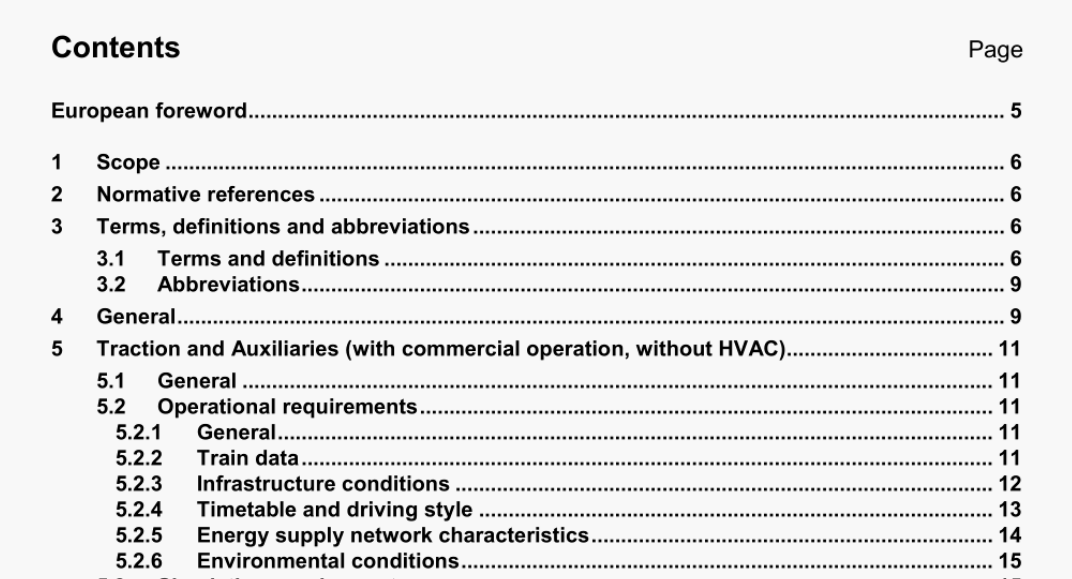

BS EN 50591:2019 pdf download.Railway Applications一Rolling Stock一Specification and verification of energy consumption

1 Scope

The purpose of this document is to support rolling stock procurement, especially life cycle cost (LCC) assessment. This document is applicable to the specification and verification of energy consumption of railway rolling stock. It establishes a criterion for the energy consumption of rolling stock to calculate the total net energy consumed, either at current collector or from the fuel tank, over a predefined service profile, to ensure that the results are directly comparable or representative of the real operation of the train. For this purpose, this document considers the energy consumed and regenerated by the rolling stock. The determination methods covered are the simulation and the measurement. This document provides the framework that gives guidance on the generation of comparable energy performance values for trains and locomotives on a common basis and thereby supports benchmarking and improvement of the energy efficiency of rail vehicles. This document does not cover the comparison of energy consumption with other modes of transportation, or even for comparison between diesel and electric traction, covering only the energy consumption of the railway rolling stock itself.

5 Traction and Auxiliaries (with commercial operation, without HVAC)

5.1 General

This clause is focused on traction energy in-service mode on a single train run for a train travelling from origin to destination location including standstill times on the way using the representative driving cycles. It includes energy related to traction auxiliaries (control, cooling and leading driver’s cab HVAC which is necessary for safe train driving) and other in commercial operation usually activated on-board systems in normal operating mode. It excludes energy related to HVAC for the passenger saloon and for the inactive driver’s cab, auxiliary equipment rarely used is also expressly omitted (for example windscreen wiper, sanding, defrosters). For the traction and auxiliary energy in service, the defined timetable for the operation over a specified line plays an important role. This document is therefore not a direct specification of detailed driving styles, instead it provides a framework which allows freedom for the user to propose sound solutions integrating a given mix of energy efficient technologies and driving styles.

5.2.5.3 Regenerative braking

Regenerative braking is the capability to generate energy during braking through the traction chain. The regenerated energy can be used by auxiliaries, comfort systems, stored in ESS or fed back to the electric traction system. The use of regenerative braking shall respect the operational rules. AC supply lines are usually able to accept the regenerative braking power, but DC supply lines can have a limited power acceptance when no other train requires the power nearby. The regenerative braking effort can also be used to supply in-service comfort functions, depending on the power needed. This capability is always present, regardless of the supply system, and avoids consuming energy from the main supply during periods of braking.

BS EN 50591:2019 pdf download