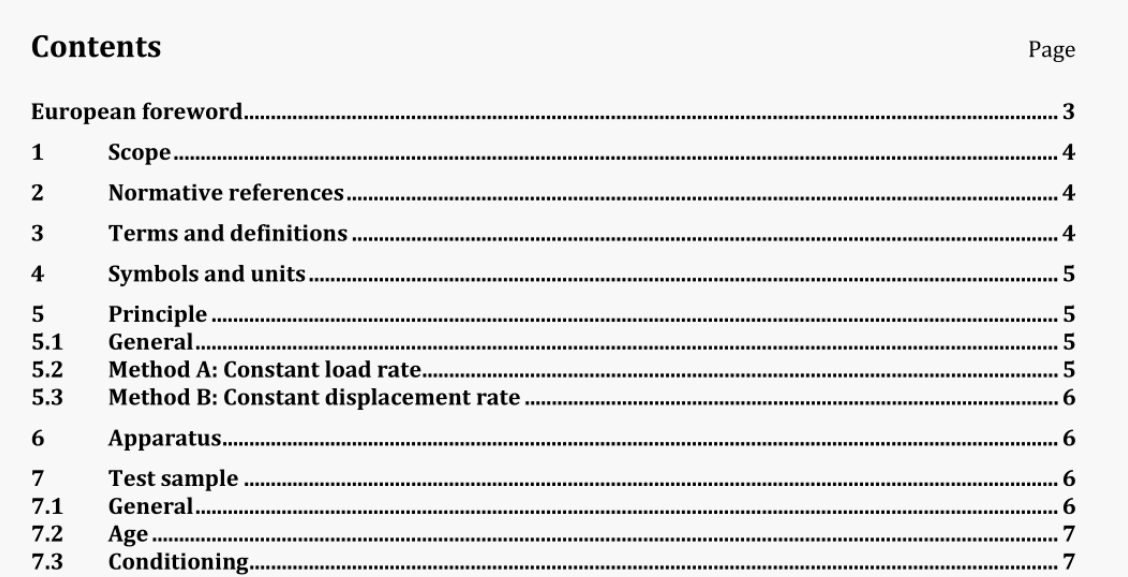

BS EN 17150:2019 pdf download.Plastics piping systems for non-pressure underground conveyance and storage of non- potable water

5.3 Method B: Constant displacement rate

The test sample is submitted to compression in one direction ( without lateral support) between two plates moving at constant speed until the maximum strength or, if applicable, a defined percentage of the initial height of the test sample (measured as a displacement of the test plates) after preload has been reached.

6 Apparatus

6.1 Compression testing machine, which shall be capable of applying loads or displacements via stiff plates. The load may be applied either directly or indirectly, e.g. by use of a lever arm arrangement. The load shall be applied (90+1)° to the bottom plate. For method A, the test machine shall have a maximum displacement rate capability in excess of 1 mm/s.

6.2 A pair of parallel plates.

Where the compression load can be applied to the test sample, the plates shall be flat, smooth and clean and shall not deform during the test to an extent that would affect the results. The deformation of the plates has to be lower than 1,0 mm during the whole test. The upper plate shall be fixed (plate type 1) or shall have the capability to rotate around one or both horizontal axes (plate type 2). If a test sample has integral protrusions, it is allowed to use an additional loose flat plate with recesses as a load distribution layer to secure acceptable contact between the surface of the test sample and the plate of the testing machine or remove the integral protrusions. The length and the width of each plate shall be greater than the length and width of the test sample.

In Figure 1, the Z-direction is the preferred vertical direction of installation. Those which are homogeneous extruded boxes shall be cut to obtain a test sample representative of the structure of the box and shall furthermore be cut with a minimum length of 0,5 m in the Z-direction. The ratio between the X-direction and Z-direction, and Y-direction and the Z-direction shall be less than 1,0. Identification of the test direction can be found in Figure 1.

8 Procedure

Choose the compression method A or B. Method A with a constant load rate of [0,50士0,05) kN/m2/s. Method B with a constant displacement rate of (1,0 + 0,1) mm/min. When performing the test, safety precautions should be taken to prevent from harm. Carry out the following procedure at a temperature of(23土2) °C. Measure the dimensions of the test sample (initial height hj; initial length l; and initial width b;) after conditioning, with an accuracy of 1 mm. Measure and record the weight of the test sample. Record the weight of the movable plate and the additional plate (if applicable). The initial surface area through which the compression load is applied onto the box can be calculated using the initial dimension measurements. Place the test sample between the two plates of the compression testing machine. The test sample should be centred on the axis of the applied load. When the test is carried out in X- or Y- direction, fixing of components may be needed compared with tests carried out in Z- Direction. The type of fixture used shall be reported. At the beginning of the test, the test sample shall be compressed with a nominal pre-load of 5 kN/m2 to 10 kN/m2. This pre-load shall be applied within 1 min and kept constant for 5 min. Record the sample height ho after applying pre-load.

BS EN 17150:2019 pdf download