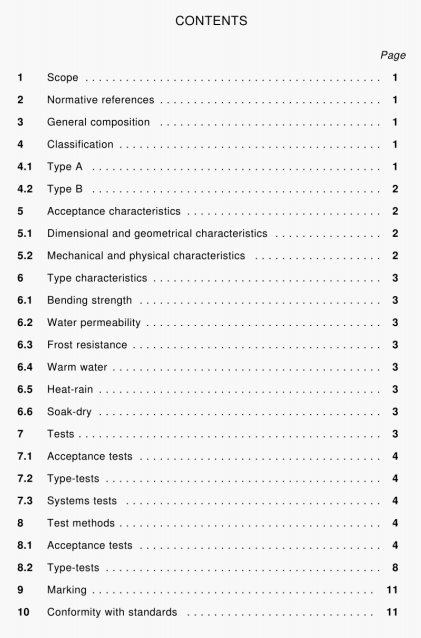

AS/NZS 2908.2:2000 pdf – Cellulose-cement products Part 2: Flat sheets.

The sheets are further classified into three categories according to their modulus of rupture.

The manufacturer shall declare the type and category of his product in his literature.

4.2 Type B

Type B sheets are not subjected to the type-tests and are intended for internal applications and external applications where they will not be subjected to the direct action of sun, rain and/or snow.

The sheets are further classified into five categories according to their modulus of rupture.

The manufacturer shall declare the type and category of his product in his literature.

NOTE I If sheets of type B are used in external applications where they are directly exposed to the weather but are protected (e.g. coating or impregnation), the weather resistance of the product is determined by the quality of the protection. Specification of this protection and meihods for control and test are outside the scope of this International Standard.

5 Acceptance characteristics

5.1 Dimensional and geometrical characteristics

5.1.1 Nominal length and width

5.1.1.1 Flat fibre-cement sheets are normally available in nominal lengths up to 3 000 mm and nominal widths up to 1 250 mm. Sheets of greater nominal lengths and widths may be supplied.

5.1.1.2 Preferred nominal dimensions for length and width may be specified in national standards taking into account that the dimensions of the sheets are determined largely by the purpose for which they are intended.

NOTE 2 The nominal dimensions (wdth and length) specified in national standards may be increased by 20 mm to 30 mm (oversize sheets) for application where the sheet is required to be cut by the user.

5.1.2 Thickness

Flat fibre-cement sheets are normally available in thicknesses from 3 mm to 30 mm, although thicknesses outside this range may be supplied. Preferred thicknesses may be specified in national standards.

Two metal rules shall be fixed at right angles along adjacent edges of the inspection surface. The straightness of each metal rule shall be at least 0,3 mm/rn and the right angle shall be accurate to at least 0.1 % (less than 1 mm deviation from normal per metre of length) or 0,001 rad.

Alternatively a portable square may be used. The same requirements for straightness and angularity apply.

b) Suitable metal rulers, capable of being read to 0.5 mm.

C) Dial gauge. reading at least to 0.05 mm. with flat parallel metal jaws, between 10 mm and 15 mm in diameter.

8.1.1.2 Measurement of width and length

For each dimension, carry out three measurements, i.e. one in the middle and one at approximately 50 mm from either end. Avoid taking the measurement over a local deformation which could be considered as a visual defect.

Smooth any rough areas.

Take each reading to the nearest 0,5 mm.

Report the individual results. Assess the results against the tolerances given in 5.1.3.

8.1.1.3 Measurement of thickness

Carry out three measurements across the width at one end of the smooth or textured sheet with the dial gauge as indicated in figure 1. Take each reading to an accuracy of 0,05 mm.

Report the individual results. Calculate the arithmetic mean and difference between extreme values. Assess the results against the tolerances given in 5.1.3.

NOTE 6 lIthe lace texture does not allow a sufficiently accurate measurement of the thickness, the thickness of tac€.textured products is determined from volume measure ment by water displacement where the test piece has been saturated betore measurement. The thickness is given by the formula.

AS/NZS 2908.2:2000 pdf – Cellulose-cement products Part 2: Flat sheets