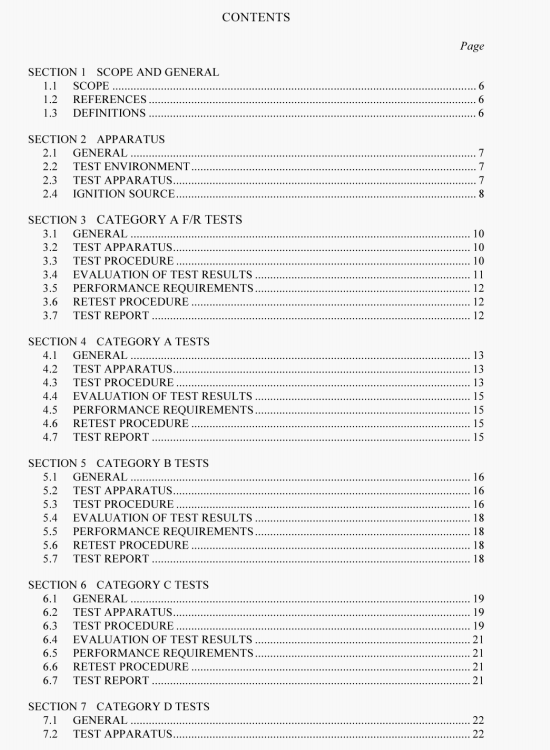

AS/NZS 1660.5.1:2005 pdf – Test methods for electric cables, cords and cond uctors Method 5.1: Fire tests- -Test for vertical flame spread of vertically-mounted bunched wires or cables.

3.1 GENERAL

This Section covers Category A F/R and relates only to power cables of conductor cross- sectional area greater than 35 mni installed on the test ladder in a spaced configuration on the front and rear to achieve a nominal total volume of non-metallic material of 7 I/rn of test sample. The flame application time is 40 mm. This method of mounting is intended for special cable designs used in particular installations when required in the cable specification. Category A F/R is not intended for general use.

The requirements for the selection of cables for testing are given in Appendix C.

NOTE: A recommended performance requirement is given in Appendix D.

3.2 TEST APPARATUS

3.2.1 General

The apparatus specilied in Section 2 shall be used.

3.2.2 Ignition source

The ignition source shall be one ribbon-type propane gas burner as specified in Section 2.

3.3 TEST PROCEDURE

3.3.1 Test sample

The test sample shall comprise a number of test pieces of cable from the same production length. each having a minimum length of 3.5 rn.

The total number of test pieces in the test sample shall be that number required to provide a nominal total volume of non-metallic material of 7 l/m of lest sample.

The test sample shall he chosen within the limitations given in Appendix C.

The test pieces forming the test sample shall be conditioned at a temperature of(20 ±lO)°C

for at least 16 h before commencing the test. The test pieces shall be dry.

3.3.2 Determination of the number of test pieces

In order to calculate the appropriate number of test pieces. it is necessary to deterniine the volume per metre of non-metallic material of one test piece.

A length of cable which shall be not less than 0.3 m long is carefully cut to ensure that the surfaces are at right angles to the cable axis, thus enabling precise measurements of its length.

The density of each non-metallic component (including cellular material) shall be measured in an appropriate way. for example Clause 8 of IF.{’ 60811-1-3. in order to obtain values expressed to the second decimal place.

Each non-metallic material C1 shall be removed from the test piece and weighed. Any nonmetallic material making up less than 5% of the total non-metallic mass of the test piece shall be assumed to have a density of 1 .0 kg/dm.

Where semi-conducting screens cannot be removed from the insulating material, the components may be considered as one for the purpose of measuring their mass and density.

AS/NZS 1660.5.1:2005 pdf – Test methods for electric cables, cords and cond uctors Method 5.1: Fire tests- -Test for vertical flame spread of vertically-mounted bunched wires or cables