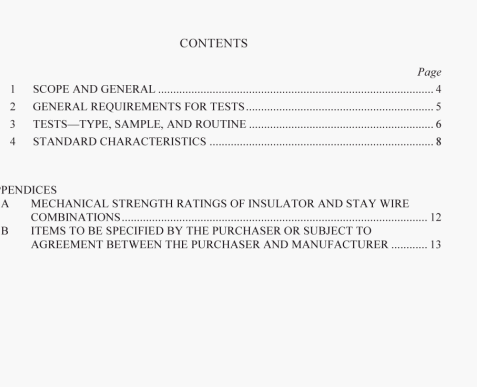

AS 3609:2005 pdf – Insulators- -Porcelain stay type- Voltages greater than 1000 V a.c..

1.4 Classification of tests

Tests shall be classified as follows:

(a) Type tests

Type tests are intended to verify the main characteristics of an insulator which depend mainly on its design. They are carried out once for a new design or manufacturing process of insulator and then subsequently repeated only shen the design or manufacturing process is changed; when the change affects only certain characteristics, only the test(s) relevant to these characteristics need to be repeated. Type tests are usually carried out on a small number of insulators.

Valid type test certificates arc those issued by an independent testing organization. confirming that these tests have been satisfactorily performed. The tests serving for the establishment of type test certificates tiiay be carried out in a laboratory other than that of the issuing organization if a qualified witness of the latter is present.

For mechanical tests, the certificate shall be valid for 10 years from the date of issue. There is no time limit for the validity of certificates for electrical type tests.

Within the above limits, the type test certificates remain valid while there is no significant disparity between the results of the type tests and subsequent corresponding sample tests.

Type tests shall be carried out only on insulators from a lot that has complied with the requirements of the releant routine tests.

(b) Sample tests

Sample tests are carried out to verify the characteristics of an insulator which can vary within the manufacturing process and the quality of the component materials of the insulator. Sample tests arc used as acceptance tests on a sample of insulators taken at random from a lot that has met the requirements of the relevant routine tests.

(c) Routine tests

Routine tests are intended to eliminate defective units and are carried out during the

manufacturing process. Routine tests are carried out on every insulator.

1.5 Marking

Each insulator shall be legibly and indelibly marked with the name or trade mark of the manufacturer and the year of manufacture.

Markings shall be printed and shall be applied before glazing.

2.1 Verification of dimensions and visual inspection

The direction of the water spray shall be from above, in the vertical plane and normal to the axis of the assembled test sample.

The water spray shall he reasonably unit form and shall cover the insulator and 150 mm of the stranded loops from the edge of the insulator.

The precipitation rate, resistivity and temperature of the water shall be in accordance with the requirements ofAS 1931.1.

2.2.4 Test voltage

While the test sample is being sprayed. a voltage of approximately sine waveform and power frequenc shall be applied betseen the stranded loops. The insulator shall then be flashed over not less than 10 times.

The r.m.s. flashover voltage to be recorded shall be the mean of not less than 10 consecutive observations, measured and corrected in accordance with the requirements of AS 1931.1.

AS 3609:2005 pdf – Insulators- -Porcelain stay type- Voltages greater than 1000 V a.c.