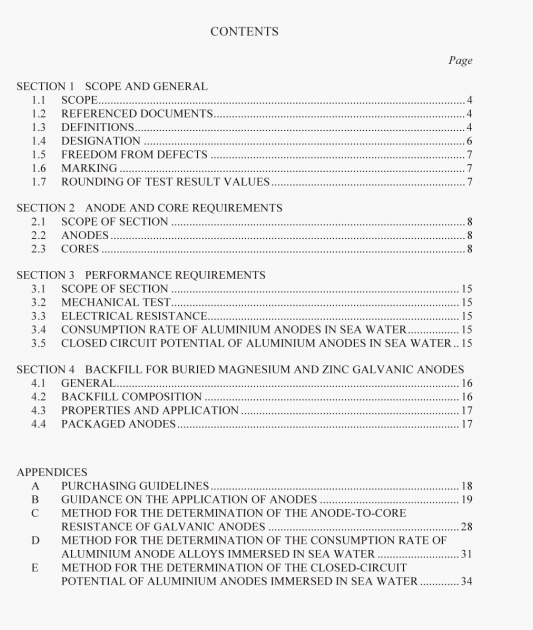

AS 2239:2003 pdf – Galvanic (sacrificial) anodes for cathodic protection.

(d) Extruded aluminium—steel wire, cold drawn.

(e) Cast aluminium—Steel rod flats either clean mill finish or abrasive blasted to Class 2, 2Y2 or Class 3 as specified by AS 1627.9.

Zinc coatings shall not be used on the steel core of aluminium alloy anodes.

2.3.3 Bonding of core to anode

Cores shall be thoroughly dried prior to manufacture of the anode. For blast cleaned steel cores, casting shall proceed within 48 hours of blast cleaning. If any visible signs of flash rusting appear by the time casting is to commence, the steel cores shall be re-cleaned.

Wire used as core material shall be free of grease and oil, which, if present, can cause bubbling in the anode material and lack of bond between the core and the anode.

2.3.4 Methods of attachment of cable for buried anodes

For buried anodes, a length of 7/1.04 insulated copper cable conforming to AS/NZS 3008.1.1. or other appropriately insulated copper cable, shall be attached to the anode core by an appropriate method. The method of attachment shall provide compliances with the mechanical requirements specified in Clause 3.2. Typical methods of attachment are as follows:

(a) For mugiwsium wocks For magnwsium anodes, typical methods of attachincnt ar shown in Figures 2.1, 2.2, 2.3 and 2.4. Afler attachment, a mastic/adhesive-lined polyethylene heat-shrink sleeve is applied to protect the joint mechanically. A crimped connection may be encapsulated with epoxy resin for this purpose.

(b) For a,,ode.c oilier than magnesium A typical method of attachment are shown in Figures 2.2, 2.3 and 2.4. After attachment, a mastic/adhesive-lined polyethylene heat- shrink sleeve is applied to protect the joint mechanically. A crimped connection may be encapsulated with epoxy resin for this purpose.

NOTES:

1 Anodes exceeding 25 kg in nett weight should he suspended by means other than by the connection cable.

2 Methods of attachment of cables for anodes suspended in water require special designs and are outside the scope of this Standard. Guidelines for cable attachment in tanks and reservoirs are provided in AS 2832.4.

2.3.5 Colour of cable insulation

The colour of the insulation of anode cables shall be red, unless otherwise specified by the purchaser.

3.2 MECHANICAL TEST

When a uniaxial force equivalent to 100 kg,or five times the mass of the anode metal,whichever is the greater,is applied to an anode containing a core, no movement of the coreor any metal insert shall occur. Where a cable is provided, a uniaxial loading of 100 kgshall not result in damage to the cable or its connections.

3.3 ELECTRICAL RESISTANCE

When determined in accordance with the test method in Appendix C, the electricalresistance of the anode to core or, if appropriate, of the anode to the near end of the cable,shall be not greater than 0.01 Q for the life of the anode.

AS 2239:2003 pdf – Galvanic (sacrificial) anodes for cathodic protection