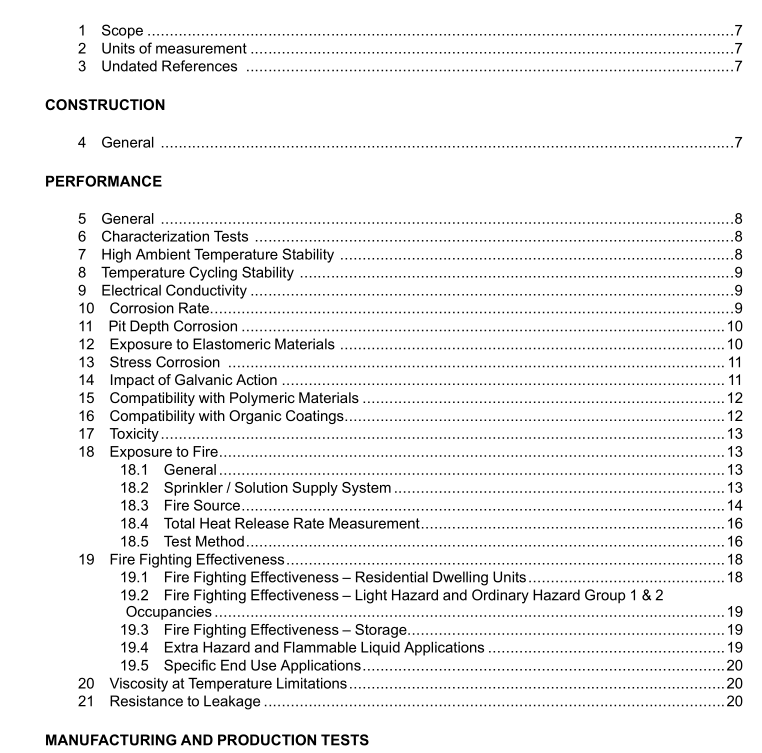

UL 2901:2019 free download Antifreeze Solutions for Use in Fire Sprinkler Systems

1 Scope

1.1 This standard covers requirements for the performance of antifreeze solutions for fire sprinklersystems.

1.2These solutions are intended for use in wet pipe sprinkler systems subject to freezing for installationin accordance with the manufacturer’s design and installation instructions, Standard for the Installation ofSprinkler Systems in One-and Two-Family Dwellings and Manufactured Homes,NFPA 13D, Standard forthe Installation of Sprinkler Systems in Low-Rise Residential Occupancies,NFPA 13R, and the Standardfor Installation of Automatic Sprinkler Systems,NFPA 13; and inspected,tested and maintained inaccordance with the Standard for Inspection,Testing and Maintenance of Water Based Fire ProtectionSystems, NFPA 25.

1.3 This standard does not contain requirements to evaluate the risk associated with products ofcombustion of antifreeze solutions.

2Units of measurement

2.1The unit designated in each requirement shall be used as the official unit for purposes of that specifictest in this standard. Where values of measurement are specified in both Sl and English units, the unit inparenthesis is for information only.

Undated References

3.1 Any undated reference to a code or standard appearing in the requirements of this standard shall beinterpreted as referring to the latest edition of that code or standard.

cONSTRUCTION

4 General

4.1 Antifreeze solutions shall be formulated in such a manner to demonstrate the ability of the solution tonot substantially contribute to the heat release rate of a fire when tested in accordance with Section 18,Exposure to Fire.

4.2For antifreeze solutions having hydraulic flow characteristics dissimilar from water,themanufacturer’s design and installation instructions shall include information regarding the appropriatemethodologies and criteria for hydraulically calculating sprinkler systems using the antifreeze solution.SeeSection 20,viscosity at Temperature Limitations and 23.1(d).

4.3 Hydrocarbon oils shall not be miscible in an antifreeze solution unless it can be demonstrated thatthe miscibility will not significantly impact the ability of the solution to comply with the requirements of thisstandard.

4.4 Antifreeze solutions shall be pre-mixed at the factory and shall not require additional mixing in thefield or additional constituents in the field.

4.5The maximum use temperature shall not be less than 150 F(66 C).

5 General

5.1 Samples of antifreeze solutions that are representative of formulation and concentration shall be subjected to the tests in Sections 6 – 22.

6 Characterization Tests

6.1 An antifreeze solution shall be characterized by conducting the following tests, using the test methods and samples indicated in Table 6.1.

7 High Ambient Temperature Stability

7.1 An antifreeze solution shall maintain stability and not separate after being exposed to a temperature of 150 ° F (66° C) for 90 days. The solution characteristics after exposure shall meet the following requirements:

a) A change of not more than 10% in viscosity and specific gravity

b) A change of not more than 6°C (11°F) in Pour Point

c) A change of not more than 3°C (5.4°F) in Freeze Point

d) A change of not more than 1 pH unit

7.2 For each concentration of antifreeze solution, at least two covered containers having a volume not less than 0.5 liters are to be filled 90% full ± 2% (10% headspace) with the antifreeze solution and placed in an air circulating oven for 90 days at a temperature of 150 ±4 °F (66 ±2 °C).

7.3 After the exposure, the sample solutions are to be subjected to the tests specified in Table 6.1.

UL 2901:2019 free download