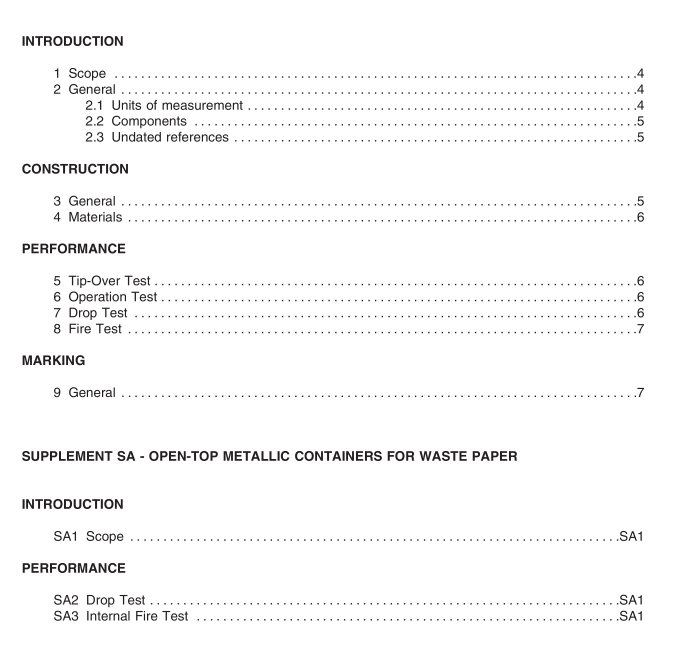

UL 1315:2017 free download Metal Waste Paper Containers

2.2 Components

2.2.1 Except as indicated in 2.2.2, a component of a product covered by this standard shall comply withthe requirements for that component.

2.2.2 A component need not comply with a specific requirement that:

a) Involves a feature or characteristic not needed in the application of the component in thevalue covered by this standard, or

b) ls superseded by a requirement in this standard.

2.2.3 A component shall be used in accordance with its recognized rating established for the intendedconditions of use.

2.2.4 Specific components are recognized as being incomplete in construction features or restricted inperformance capabilities. Such components are intended for use only under limited conditions,such ascertain temperatures not exceeding specified limits, and shall be used only under those specific conditionsfor which they have been recognized.

2.3 Undated references

2.3.1 Any undated reference to a code or standard appearing in the requirements of this standard shallbe interpreted as referring to the latest edition of that code or standard.

CONSTRUCTION

3 General

3.1 Vertical seams and bottom joints of the container or of metal liners,if provided,shall belocked-seamed or welded.

3.2 The head or cover shall be provided with means for retaining it in place when assembled on thecontainer body or may be of the type consisting of a one piece container body/head assembly that fits overan internal liner.

3.3 The means of retaining the head or cover to the container body may be an indented or beadedconstruction providing a snap type fit between the parts or it may be permanently attached by means ofa hinge or the equivalent.

4 Materials

4.1 The container body and the head or cover shall be made of sheet steel or of corrosion resistant metalas described in 4.2.

4.2 The container body and the outside surface of the head or cover shall be either painted or hot-dippedgalvanized unless made of corrosion resistant metal.

PERFORMANCE

5 Tip-Over Test

5.1 The test is to be conducted on all containers which do not have a permanently attached head orcover, that is hinged, are not of the type consisting of a one piece container body/head assembly, and donot have handles on the sides of the container body.

5.2 The container shall be able to be lifted by the head or cover after being tested as specified in 5.3.5.3 One container of each type is to be tipped over five times, at least once on each side if flat sided orevenly distributed around the circumference if round.

6 operation Test

6.1 Containers provided with a self-closing lid are to be subjected to 6,000 cycles of operation. The lidshall not become inoperative to the extent that it will affect the results of the fire test.

7 Drop Test

7.1 Containers having less than 30 gallons (112.7 liters) of capacity, or all internal liners, if provided, areto be tested as specified in 7.3, prior to the fire test.

7.2 Containers having less than 30 gallons (112.7 liters) of capacity, and all internal liners, if provided,shall not rupture, break apart or be damaged to the extent that it will affect the results of the Fire Test,Section 8, after being tested as specified in 7.3.

7.3 Each test sample to be subjected to the fire test is to be dropped five times from a height of 5 feet(1.52 m) onto a concrete floor, so as to strike once on the bottom, the top, the side, a top corner and abottom corner.The tests are to be conducted on samples of the liner and on samples of the container withthe liner in place.

UL 1315:2017 free download