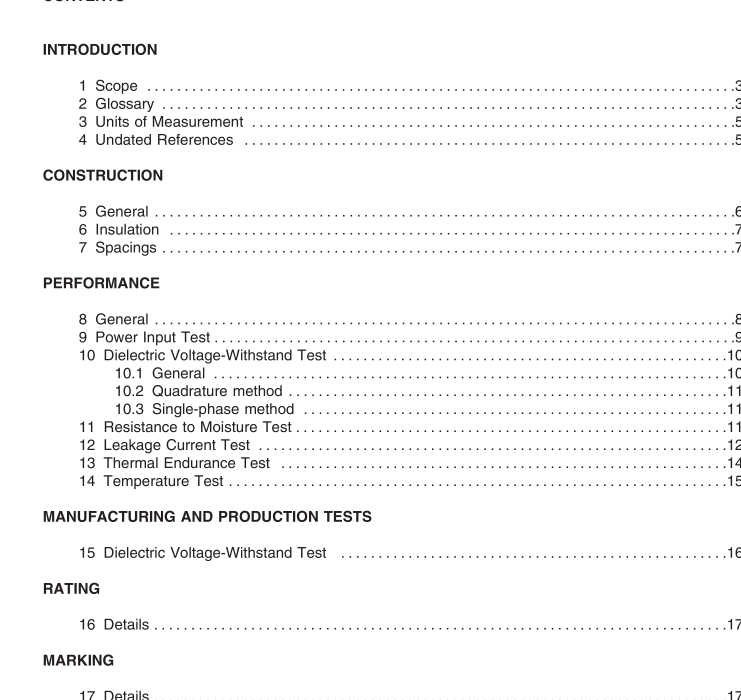

UL 1030:2017 free download Sheathed Heating Elements

5 General

5.1 The acceptability of a heating element in any equipment or appliance depends upon its ability to withstand continued use under the conditions that prevail in actual service. In addition to the requirements contained herein, further considerations and investigations may be necessary, based upon the intended installation and use of the sheathed heating element.

5.2 A sheathed heating element shall employ materials and components throughout that meet the intent of the requirement, and shall be made and finished with the degree of uniformity and grade of workmanship practicable in a well-equipped factory.

5.3 If a material or alloy not included in Table 14.1 , a material provided with a coating, or a composite sheath utilizing dissimilar materials inside and outside is used, it shall be investigated to determine that the material is acceptable for the purpose and that it affords protection equivalent to that of the materials included in Table 14.1.

5.4 After being formed, the sheath of a heating element shall have a thickness not less than specified in Table 5.1.

5.5 The values in Table 5.1 are intended to specify a minimum thickness for a sheath made of steel, titanium, copper, copper-clad steel, or steel and nickel alloys. Increased thickness may be required, based upon the particular end-use application of the heating element. A sheath made of aluminum or aluminum alloy and a sheath having a thickness less than specified in Table 5.1 is to be investigated under conditions of actual service to determine if it has the necessary mechanical properties and will withstand the most severe conditions likely to be met in service.

6 Insulation

6.1 An insulating washer, a bushing, or the like, that is an integral part of a heating element shall be of a material resistant to moisture, such as porcelain, and shall be acceptable for use at the maximum temperature to which it will be subjected under conditions of actual use. Such parts shall have adequate mechanical strength and rigidity to withstand the stress of actual service.

6.2 Insulating material employed in an integral part of a heating element, such as a terminal block, or the like, shall be strong, not easily ignited, and resistant to moisture. A material other than porcelain, phenolic, or one that is known to be acceptable for the support of current-carrying parts shall be investigated under conditions of actual service to determine if it has the necessary electrical and mechanical properties and will withstand the most severe conditions likely to be met in service.

6.3 The thickness of magnesium oxide (MgO) or other similar insulating material between the resistance element and the inside of the sheath, and the material of an end seal between the terminal pin and the inside of the sheath shall not be:

a) Less than 0.016 inch (0.41 mm) for elements rated 300 volts or less, and

b) Less than 0.031 inch (0.79 mm) for elements rated more than 300 volts.

UL 1030:2017 free download