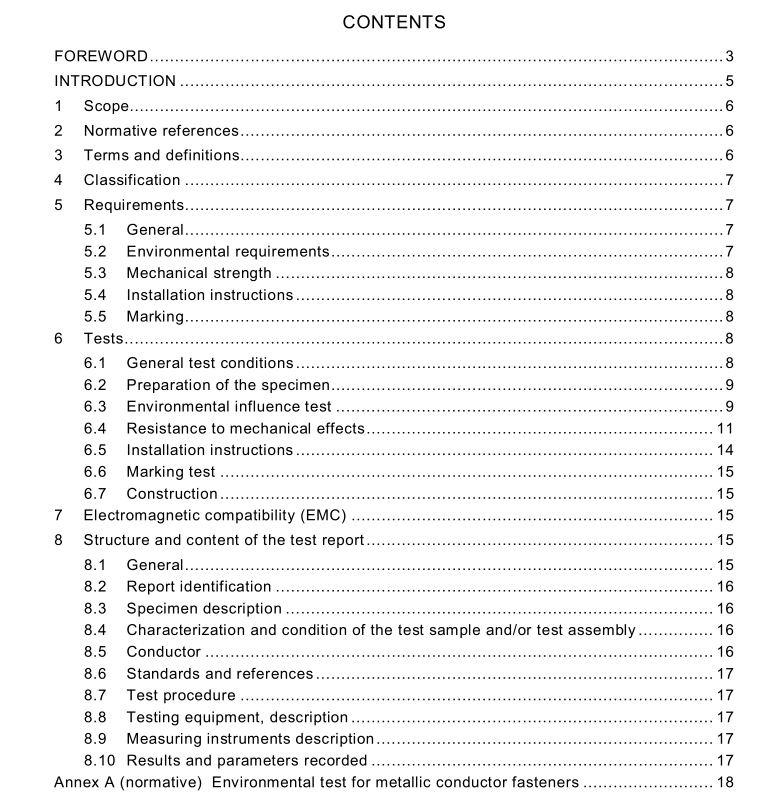

IEC 62561-4:2010 pdf free download Lightning protection system components (LPSC) – Part 4: Requirements for conductor fasteners

1 scope

This Part 4 of lEC 62561 deals with the requirements and tests for metallic and non-metallicconductor fasteners that are used in conjunction with the air termination,down conductor andearth termination system.

This standard does not cover the fixing of conductor fasteners to the fabric/membranelgravelroofing of structures due to the vast number and types used in modern day construction.

LPsC may also be suitable for use in hazardous atmospheres.Regard should then be takenof the extra requirements necessary for the components to be instaled in such conditions.

2Normative references

The following referenced documents are indispensable for the application of this document.For dated references, only the edition cited applies. For undated references, the latest editionof the referenced document (including any amendments) applies.

IEC 60068-2-52:1996,Environmental testing – Part 2-52:Tests – Test Kb: Salt mist, cyclic(sodium chloride solution)

IEC 60068-2-75:1997,Environmental testing – Part 2:Tests – Test Eh:Hammer testslEC 62305(all parts),Protection against lightning

IEC 62305-3:2006,Protection against lightning – Part 3: Physical damage to structures andlife hazard1

ISO 4892-2:2006, Plastics – Methods of exposure to laboratory light sources – Part 2: Xenon- arc lamps

ISO 4892-3:2006,Plastics – Methods of exposure to laboratory light sources – Part 3:Fluorescent Uv lamps

ISo 4892-4:2004,Plastics – Methods of exposure to laboratory light sources – Part 4: Open-flame, carbon-arc lamps

ISo 6988:1985,Metallic and other non-organic coatings – Sulphur dioxide test with generalcondensation of moisture

Iso 6957:1988,Copper alloys – Ammonia test for stress corrosion resistance

3Terms and definitions

For the purpose of this document, the following terms and definitions apply.

4 Classification

Conductor fasteners are classified as follows:

a) According to material

– metallic (e.g. hot dip galvanized steel, copper, aluminium, stainless steel);

– non-metallic (e.g. PVC, plastics);

– composite (combination of metal and plastic);

b) According to fixing arrangement of the conductor within the conductor fastener

– with screws;

– without screws (e.g. clips, springs);

c) According to conductor clamping arrangement

– conductor fasteners that are designed to clamp the conductor;

– conductor fasteners that are designed to clamp but allow axial movement of the conductor.

5 Requirements

5.1 General

The conductor fastener shall carry out its function of clamping the conductor in an acceptable and safe manner when subjected to mechanical influences, lightning discharge stress and environmental influences.

Conductor fasteners shall comply with the tests given in Clause 6. The material of the conductor fastener shall be compatible with the conductor it is fastening and the surface material onto which it is mounted.

5.2 Environmental requirements

5.2.1 Corrosion resistance

Metallic or composite conductor fasteners shall withstand corrosion effects.

Compliance is checked following the manufacturer’s declaration for the classification of the conductor fastener in accordance with Clause 4 and by test specified in 6.3.2 and 6.3.4.

IEC 62561-4:2010 pdf free download