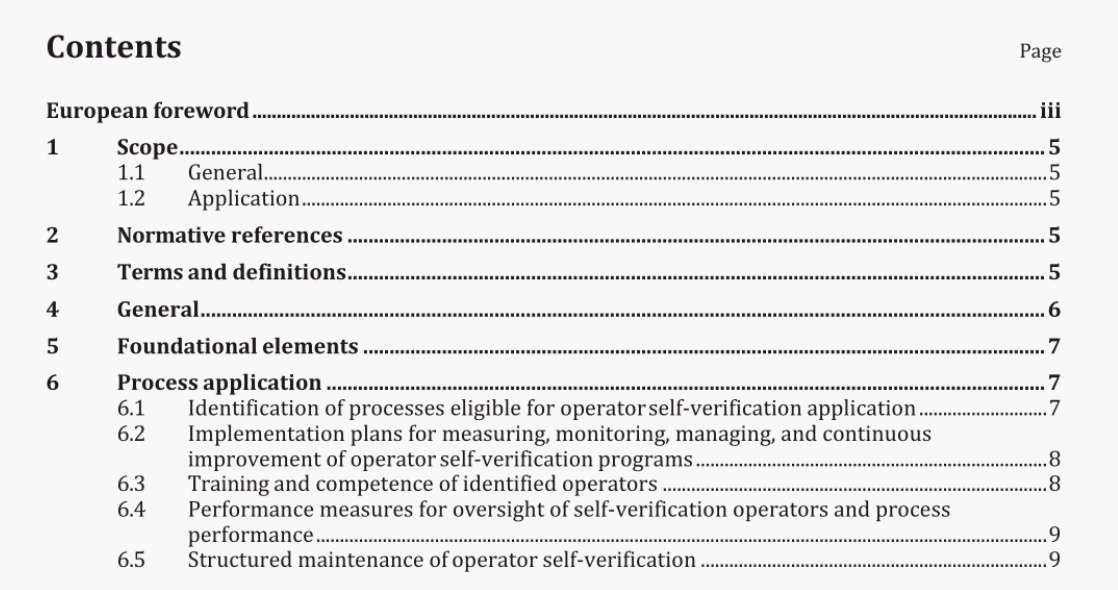

BS EN 9162:2018 pdf download.Aerospace series – Aerospace Operator Self-Verification Programs

1 Scope

1.1 General

This document identifies the basic elements and provides a standard for structuring operator self-verification programs within the aviation, space, and defence industry for producers of commercial and military aircraft and weapons platforms, space vehicles, and all related hardware, software, electronics,engines, and composite components.

The requirements specified in this standard are complementary (not alternative) to contractual and applicable statutory and regulatory requirements. Should there be a conflict between the requirements of this document and applicable statutory or regulatory requirements, the latter shall take precedence.

1.2 Application

Operator self-verification programs are applied to improve the overall efficiency and product quality of processes considered stable and capable of fulfilling all requirements, as determined by the implementing organization. Operator self-verification programs are not stand-alone processes,but augment an existing quality management system. Its application can be made where inspection activities are currently deployed.

2 Normative references

The following documents are referred to in the text in such a way that some or all of their content constitutes requirements of this document. For dated references, only the edition cited applies. For undated references, the latest edition of the referenced document (including any amendments) applies.

EN 9100, Quality Management Systems一Requirements for Aviation, Space and Defence Organizations

EN 9110, Quality Management Systems一Requirements for Aviation Maintenance Organizations

NOTE Equivalent versions (e.g., AS, EN, JISQ, SJAC, NBR) of the IAQG standards listed above are published internationally in each IAQG sector.

6 Process application

A program implementation plan shall include the communication of program objectives and intent,development and deployment of associated training, establishment of process performance measures,and the methods for sustaining such operations. Subordinate documentation can be developed and deployed, as deemed necessary, to provide specific or detailed direction/instructions for the work force,management, administrative personnel, program/ process records and record retention, etc.

6.1 ldentification of processes eligible for operator self-verification application

6.1.1 When identifying potential processes for application of operator self-verification, either selectively or at an organization-wide basis, the implementing organization shall consider and select processes based on:

a) the demonstrated stability of the process through such methods as first article inspection,performance results, and process generated nonconformities identified during the established process performance review period/cycle time;

b) the detectability of product/ process non-conformance.

6.1.2 Operator self-verification shall not include those processes considered by the organization,customer, and/ or regulatory authorities as“critical processes”, unless adequate mitigation of risk is agreed to, in place, and proper delegation has been specified.

6.13 When applying a self-verification program to critical processes, the implementing organization shall consider and select processes based on the acceptable levels of perceived risk associated with the candidate process; a defined process for risk analysis shall be used.

NOTE The selection of processes is most effective when performed by a multi-disciplined group (e.g, Manufacturing, Quality Assurance, Manufacturing Engineering, Engineering).

BS EN 9162:2018 pdf download