BS EN 16837:2018 pdf download.Surfaces for sports areas – Determination of linear shoe/surface friction

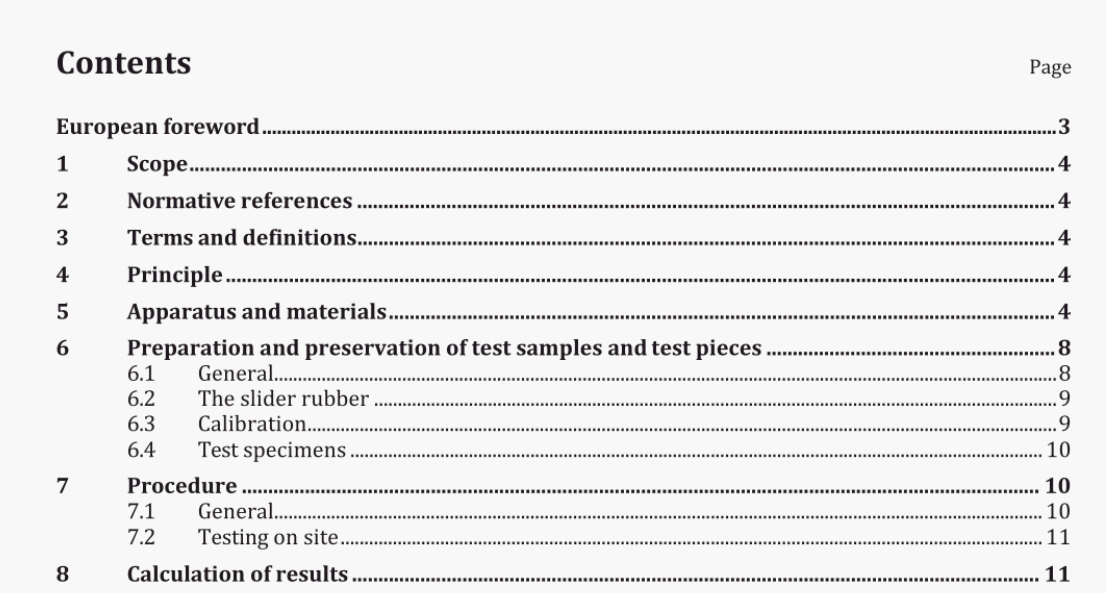

1 Scope

This European Standard specifies a test method for the determination of shoe/surface friction of synthetic sports surfaces. The method can be used for the assessment of both indoor and outdoor sports surfaces.

NOTE This method is not considered suitable for long pile synthetic turf surfaces.

2 Normative references

The following documents, in whole or in part, are normatively referenced in this document and are indispensable for its application. For dated references, only the edition cited applies. For undated references, the latest edition of the referenced document (including any amendments) applies.

ISO 48, Rubber, vulcanized or thermoplastic一Determination of hardness (hardness between 10 IRHD and 100 IRHD)

ISO 4662, Rubber, vulcanized or thermoplastic一Determination of rebound resilience

ISO 7619-2, Rubber, vulcanized or thermoplastic一Determination of indentation hardness一Part 2: IRHD pocket meter method

3 Terms and definitions

For the purposes of this document, the following terms and definitions apply.

3.1 slip resistance

property of the surface which limits the relative movement between the contact patch of footwear (slip) and the sports surface

3.2 friction

resistance to relative motion between two bodies in contact

3.3 vertical load

vertical force exerted on the sports surface by the test foot

3.4 linear shoe/surface friction

property measured which is expressed as Pendulum Test Value (PTV)

4 Principle

The Pendulum Tester incorporates a spring-loaded slider (test foot) made of a standard rubber attached to the end of a pendulum. On releasing the pendulum from a horizontal position, the loss of energy as the test foot passes over the test surface is measured by the reduction in length of the upswing using a

calibrated scale.

5 Apparatus and materials

The pendulum test shall incorporate the essential features given below and as illustrated in Figure 1. All bearings and working parts shall be enclosed as far as possible, and all materials used shall be treated to prevent corrosion under wet conditions.

6.2 The slider rubber

The slider rubber shall be vulcanized or bonded onto the backing. The test foot shall be provided with a central pivoting axis which shall be mounted on the end of the pendulum arm in such a way that, when the arm is at the lowest point of its swing with the trailing edge of the slider rubber in contact with the test surface, the plane of the slider is angled at (26士3)° to the horizontal. In this configuration the slider can turn about its axis without obstruction to follow the unevenness of the test surface as the pendulum swings. The slider rubber shall be spring-loaded against the test surface. The nominal static force on the test foot as set by the equipment calibration procedure, defined in Annex A, shall be (22,2土0,5) N in its median position. The change in the static force on the slider shall not be greater than 0,2 N/mm deflection of the slider. The initial resilience, measured by the Libke Rebound Test in accordance with ISO 4662, and the hardness of the slider rubber, measured by the International Rubber Hardness Degrees (IRHD] in accordance with ISO 48, shall conform to Table 1. It shall have a certificate of conformity including the name of the manufacturer and date of manufacture.

BS EN 16837:2018 pdf download