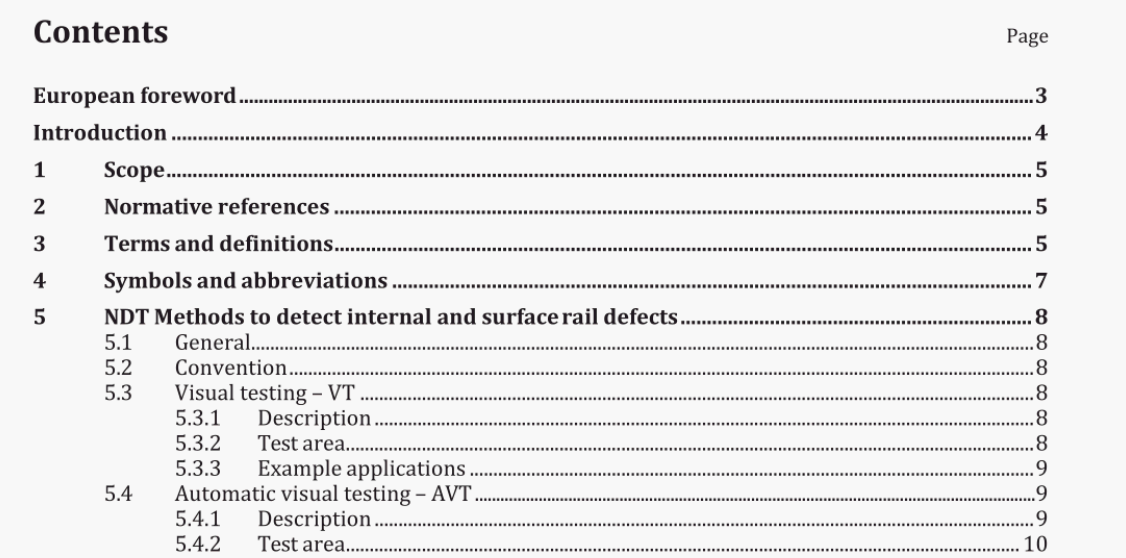

BS EN 16729-3:2018 pdf download.Railway applications – Infrastructure – Non- destructive testing on rails in track

1 Scope

This part of this European Standard specifies the NDT methods used to detect internal and surface rail defects and the suitability of each method for the detection and evaluation of typical rail defects of rails installed in track.

This part of this European Standard does not specify the assessment criteria of rail defects and the derived actions.

This part of this European Standard applies only to rail profiles meeting the requirements of EN 13674-1.

2 Normative references

The following documents are referred to in the text in such a way that some or all of their content constitutes requirements of this document. For dated references, only the edition cited applies. For undated references, the latest edition of the referenced document (including any amendments) applies.

EN 16729-1:2016, Railway applications一Infrastructure一Non-destructive testing on rails in track一Part 1: Requirements for ultrasonic inspection and evaluation principles

3 Terms and definitions

For the purposes of this document, the following terms and definitions apply.

ISO and IEC maintain terminological databases for use in standardization at the following addresses:

●IEC Electropedia: available at http://www.electropedia.org/

●ISO Online browsing platform: available at http://www.iso.org/obp

3.1 damaged rail

rail which is neither cracked nor broken, but which has other defects

3.2 cracked area

part of the rail with a localized discontinuity of material

3.3 broken rail

rail which has separated into two or more pieces;orrail from which a piece of metal becomes detached from the rail head, with a gap of more than 50 mm in length and more than 10 mm in depth resulting in a running band less than 30 mm in width

NOTE See Figure 1 and Figure 2 for the first part of the definition, and Figure 3 for the second part.

5.3.1 Description

Visual testing of rails is a direct visual examination of the condition of a section of rail, specifically the surface of the rail head, to detect the presence of a defect, define and measure it. Visual Testing can be divided into two categories:

一general visual testing;

一detailed visual testing. General visual testing (for example walking the track) is used for detecting the presence of defects.

In this case, the rail shall be illuminated, if necessary, with auxiliary lighting to attain a minimum of 160 lx and the distance between the viewing position and the rail surface may be more than 600 mm. Detailed visual testing is used for defining and measuring defects (for example the assessment of RCF). In this case, if necessary, the rail shall be illuminated with auxiliary lighting to attain a minimum of 500 lx. The distance between the viewing position and the rail surface shall not be more than 600 mm with a viewing angle of not less than 30° from the rail surface.

BS EN 16729-3:2018 pdf download