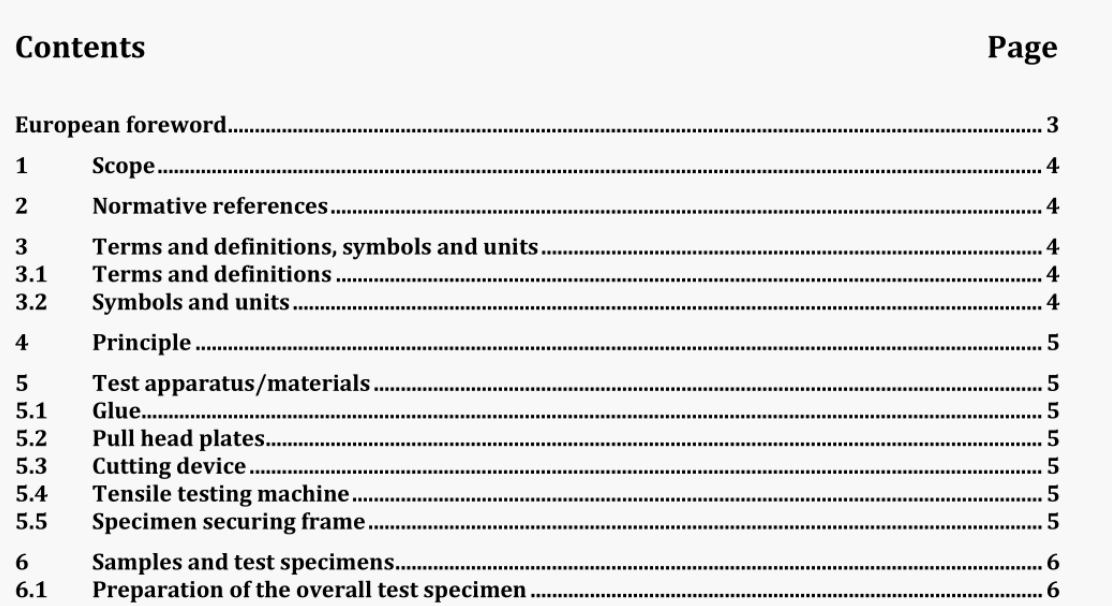

BS EN 13494:2019 pdf download.Thermal insulation products for building applications一Determination of the tensile bond strength of the adhesive and of the base coat to the thermal insul ation material

1 Scope

This document specifies the test apparatus, materials and procedures for determining the tensile bond strength of an adhesive, a reinforced base coat or a rendering system to a thermal insulation product for use as components in external thermal insulation composite systems (ETICS).

The test method described in this document is not applicable to PU foam adhesives. For testing such products see EN 17101.

2 Normative references

The following documents are referred to in the text in such a way that some or all of their content constitutes requirements of this document. For dated references, only the edition cited applies. For undated references, the latest edition of the referenced document (including any amendments) applies.

EN 1602, Thermal insulating products for building applications一Determination of the apparent density

EN 1607, Thermal insulating products for building applications 一Determination of tensile strength perpendicular to faces

EN 17237,1 Thermal insulation products for buildings一External thermal insulation composite systems with renders (ETICS)一Specification

5 Test apparatus/ materials

5.1 Glue

The glue shall be capable of providing a strong bond between the metal pull head plates, the adhesive, the reinforced base coat or the rendering system. The glue shall also be capable of achieving a strong bond between the optional substrate and the thermal insulation product. Solvent free epoxy or polyurethane glue has been found suitable for this purpose. The glue shall not damage or react chemically with the adhesive, thermal insulation product, the reinforced base coat or the rendering system. It shall not influence the results.

5.2 Pull head plates

The square metal pull head plates with a thickness of at least 5 mm shall have dimensions of (50士1)mmx (50士1) mm, (100+ 1) mmx (100士1) mm, (150士1) mmx (150+1) mm or (200+ 1) mmx (200 + 1) mm. The pull head plates shall have sufficient rigidity to prevent any negative influence on the test results. They shall have a central fitting for the connection to the tensile testing machine via a self-aligning attachment (universal coupling) to ensure that an even distribution of tensile stress is applied to the individual test specimen during test. The face of the pull head plates to which the glue is to be applied shall be flat to a tolerance of +0,5 mm per 100 mm length.

5.5 Specimen securing frame

The frame is used in conjunction with the tensile testing machine to clamp the individual test specimen to the base of the machine and to ensure the applied load is distributed evenly onto the surface of the specimen. The frame is made of metal plates with a minimum thickness of 5 mm. The size of the frame should allow it to sit within the upper surface area of the test specimen. The square recess of the frame shall be (10土1) mm larger than the individual test specimen. Figure 1 shows a specimen securing frame for the tensile testing machine on the overall specimen with individual test specimens.

BS EN 13494:2019 pdf download