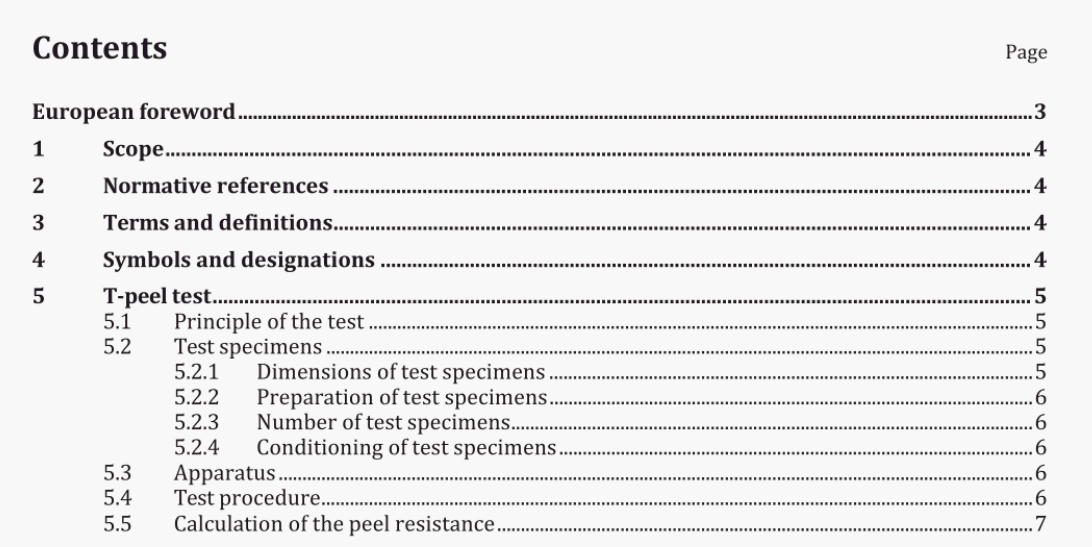

BS EN 12814-4:2018 pdf download.Testing of welded joints of thermoplastics semi-finished products

1 Scope

This document specifies the dimensions, the method of sampling and the preparation of the test specimens, and also the conditions for performing the peel test perpendicular to the weld in order to determine the peel resistance and the failure behaviour. A peel test can be used in conjunction with other tests (e.g. tensile creep, macroscopic examination..) to assess the performance of welded assemblies, made from thermoplastics materials. Peel tests are applicable to overlap welded assemblies made from thermoplastics materials. The T-peel test as defined in Clause 5 will be used only for assessing welded sheet assemblies. This test is not applicable to welded test pieces containing sheets of different nominal thickness. The decohesion test as defined in Clause 6 will be used only for assessing electrofusion joints with nominal thickness of pipe/itting greater than 10 mm. For socket fusion and for electrofusion socket joints with nominal outside diameter less than or equal to 90 mm, a crush test will be used, as defined in Clause 7. The crush test can also be used for electrofusion joints with outside diameters greater than 90 mm. The crush test for electrofusion saddle joints will be performed in accordance with ISO 13955 [1]. NOTE A decohesion test is also defined in ISO 13954 [2]. The tests defined in this standard are not intended to be used for assessment and/or qualification of thermoplastic fittings that already have their own requirements, e.g. polyethylene fttings according to EN 1555-3 [3] and EN 12201-3 [4].

5.2.2 Preparation of test specimens

The time between the end of the welding operations and the start of machining operations, shall be atleast 8 h.

The welded test specimens shall be cut perpendicular to the welded joint.

The test specimens shall be cut with parallel sides as shown in Figure 1.

During cutting, heating of the test specimen should be avoided.

Cutting of the test specimen shall not produce notches.

After cutting, a visual examination of the weld should be carried out and any imperfections, as defined in EN 14728 [5], recorded.

Each test specimen shall be marked so that its original position in the test piece can be identified.

5.2.3 Number of test specimens

At least 5 specimens shall be tested for each welded test piece unless otherwise specified in the relevant application standard.

5.2.4 Conditioning of test specimens

No heat treatment or mechanical straightening operations shall be carried out on the test specimen.

After machining, the test specimens shall be conditioned at least 2 h at the testing temperature.

5.3 Apparatus

The test equipment shall conform to the requirements given in ISO 5893.

The crosshead displacement shall be continuous, uniform and in accordance with Table 3.

After setting, the rate shall not vary during the course of any test or series of tests by more than+5 % of the mean rate and shall remain within the limits imposed in Table 3.

The force shall be measured and recorded with an accuracy of+2 %.

BS EN 12814-4:2018 pdf download