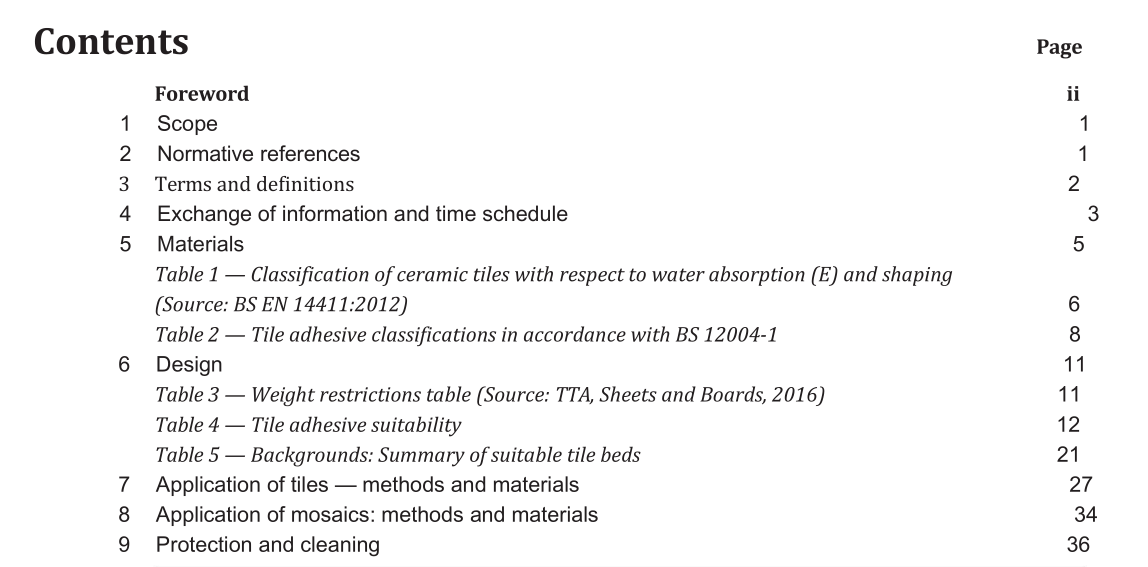

BS 5385-1:2018 pdf download.Wall and floor tiling – Part 1: Design and installation of ceramic, natural stone and mosaic wall tiling in normal internal conditions – Code of practice

1 Scope

This part of BS 5385 gives recommendations for the design and installation of ceramic, natural stone and mosaic wall tiling in normal internal conditions; a description of tile types can be found in Annex A. This part of BS 5385 deals with classes and types of background and their suitability to receive tiling using the following fixing methods: a) bedding in cementitious adhesives on an intermediate substrate or as a direct bedding method; b) bedding in organic‑based adhesive (dispersion or reaction resin) on an intermediate substrate or as a direct bedding method; and c) bedding in cement:sand mortar on rendering or as a direct bedding method. Natural stone modular tiles as defined in BS EN 12057 are included within the scope of this British Standard, but natural stone slabs (i.e. units with nominal thickness greater than 12 mm thick) are excluded. Ceramic tile fittings for corners and edges etc., are less readily available than hitherto, and are excluded from this British Standard. Where the tiling installation is to meet special functional or environmental requirements, or to assist in counteracting potentially detrimental effects on the installation and/or the structure, see BS 5385‑ 4. The special conditions dealt with in BS 5385‑4, for example, swimming pools, shower areas, etc., are listed in Annex B. Agglomerated stone tiles and slabs are not included within the scope of this British Standard. Dimensionally similar to natural stone tiles, they possess different physical and chemical characteristics as a result of the various natural stone, mineral and binder constituents from which they are manufactured.NOTE 1 Agglomerated stone tiles and slabs are natural stone and/or mineral fragments set in a binder subsequently cut to form tiles with a surface that is normally ground and polished to finish. Metal, plastic, resin or mirror tiles and glass tiles of similar construction are not included within the scope of this British Standard, as these require different techniques, adhesives etc., to traditional tiles. NOTE 2 Mirror tiles are tiles manufactured from float or plate glass with an applied backing. For the purposes of this British Standard “normal conditions” means normal environmental temperatures and humidity. However, it is not to be inferred from this that all recommendations made in this British Standard are unsuitable for more extreme conditions. Manufacturers’ instructions contain limitations of their products.

4.3 Time schedules

The time schedule for the whole building work should be planned in the initial stages before operations are begun and, where possible, in consultation with those responsible for carrying out the work of each of the trades concerned. In preparing the time schedule, each operation should be considered in relation to others. Assessment should be made of the most economical use of general plant and scaffolding by all trades, also to ensure that the various trades do not interfere unduly with each other’s work. Before tiling commences, at least six weeks should be allowed under good drying conditions for a new concrete or masonry wall to dry out. Whenever rendering is applied onto old or new concrete, it should be left for at least a further two weeks. New gypsum plasterwork should be left for at least four weeks. For some types of limestone and marble there should be longer drying times.

BS 5385-1:2018 pdf download