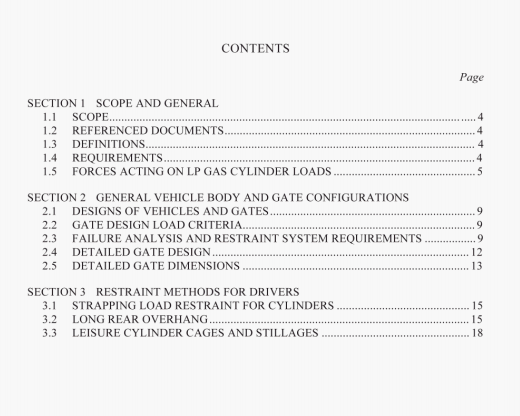

AS 5714:2015 pdf – Load restraint for LP Gas cylinder distribution.

2.3.4 Loss of cylinders through central support failure

For the cylinder truck design concept being covered in this Clause, 50% of side forces are resisted by the central support. The maximum length of the LP Gas storage space is 8.4 m; therefore, the central support shall resist the LP Gas cylinder-related forces with a sakty factor of 2.5. These forces are—

(a) a shear force of 18, 500 N: and

(b) a bending moment force of 2, 510 Nm.

2.3.5 Other detailed design considerations to minimize the risk of failure

Where there is a sudden change in shape of a structural member, stress concentration will occur. The safety factor may he increased.

A weld joint shall be designed so forces are transferred through welds in shear. It is poor welding practice and not recommended that a weld be in pure tension.

For example, using rectangular hollow section (RHS) steel tubes for the central support for the headboard uprights, butt welding these against the top of the coaming rail and welding around the point of contact is not recommended. The minimum material that will resist the forces and provide the required safety margins is a 100 mm x 50 mm x 4 mm RHS tube with the 50 mm dimension lined up with the 50 mm width of the coaming rail.

The method in which this support is attached to the coaming rail is critical. The

100 mm x 50 mm x 4 mm RHS tube shall not be butted to the coaming rail and welded

around its circumference. Any internal weld defect may crack and fail as maximum loads

(lension plus shear plus bending moment) are applied to that weld.

Plates, angles or other devices shall be used to ensure that the welds resisting failure are not in tension.

Two possible arrangements are shown in Figure 2.2. with all edges and corners smoothed and rounded. Other detailed designs that achieve the same result may be used.

(g)The pins shall be welded at the top flange of the coaming rail to give maximum gate

clearance to the ground, and the length of welds to the coaming rail on each side shallbe at least 40 mm.

NOTE: The tubing forming the other part of the hinge should be at least 40 mm long andeither heavy 15 mm nominal bore circular hollow section (CHS) tube with an outsidediameter of 21.3 mm and a wall thickness of 3.2 mm or machined tube with a minimum wallthickness of 4 mm.

(h)

Suitable top latches that positively lock the gates shall be fitted at each end of thegates. Such latches shall have pins,barrels or bars at least 10 mm in diameter if inclose to pure shear, or larger if subject to bending moments.

NOTE: If the locking part is a flat plate style, it should be 40 mm wide and 4 mm deep oralternately around 25 mm wide and 5 mm thick.

(i)Gates shall not exceed 3.2 m overall length.2.5DETAILED GATE DIMENSIONS

Table 2.2 shows the centre of mass of the various types of LP Gas cylinders regularlycarried and recommended locations of gate cross members. These spacing are illustrated inFigure 2.3.

Gates shall be a minimum of 70% of the height of the cylinders they are used to contain or55% of the height of any stillage they contain. Due consideration shall be given to groundclearance for gates that are hinged.

AS 5714:2015 pdf – Load restraint for LP Gas cylinder distribution