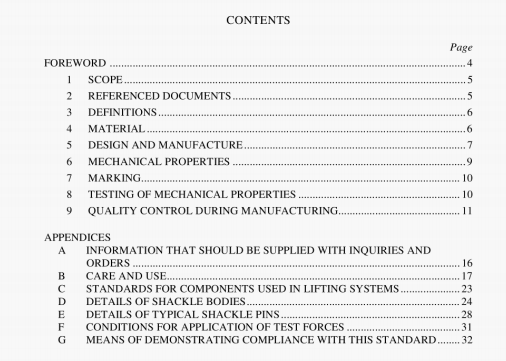

AS 2741:2002 pdf – Shackles.

Before use, shackles should be inspected to ensure the following apply:

(a) The markings are legible.

(b) The pin is of the correct type.

(c) The threads of the pin and the body are undamaged.

(d) The body and the pin are not distorted.

(e) The body and the pin are not unduly worn.

(f) The body and the pin are free from nicks, gouges, cracks and corrosion.

B1.2 Periodic

Shackles in use should he subject to periodic thorough examination by a competent person.

The period between such examinations will depend upon the amount of use.

B2 SELECTION

B2.1 Type

Select the correct type of shackle for a particular application from the information given in Paragraph B4.

B2.2 Working load limit (WLL)

For applications involving two or more attachments to a shackle (which would apply nonlinear forces), the WLL should be determined in consultation with the manufacturer.

The WLL for each application of a shackle shall be derived as follows:

(a) Maximum load The maximum load that may be supported by a shackle under general conditions of use.

(b) General conditions of use General conditions of use are equivalent to a group classification of crane mechanisms of M3, as specified in AS 1418.1.

(c) Non-geizeral-use value Under other than general conditions of use (e.g., severe conditions, hazardous conditions, conditions directly involving the safety of personnel), the WLL shall be derived to conform to the group classification of crane mechanisms as specified in AS 1418.1 for the conditions of use that apply.

NOTES:

1 Under specified or unusual conditions of use (e.g., a high temperature environment, handling dangerous substances), the regulatory body may require the use of a derating that is greater than that specified in AS 1418.1,

2 Where the shackle is an integral part of a crane, the derating for the shackle shall be the same as that used for the crane.

B3ASSEMBLY

When assembling a shackle, the following requirements apply:

(a) Ensure that the pin is of the correct length,so that it penetrates the full depth of the

screwed eye and allows the collar of the pin to bed on the surface of the drilled eye.

(b) Ensure that the pin is screwed securely into the shackle body, so that the collar of thepin is seated on the shackle body.

(c)Incorrect seating of a pin may be due to a bent pin, a tightly fitting thread or

misalignment of the pin holes. Such a shackle shall be withdrawn from service.

(d) Never replace a shackle pin with one of a different grade or specification, as it maynot be suitable for the loads imposed.

(e) Shackles permanently attached to a lifting device shall have their pins secured,toprevent unintended release,such as by seizing or mousing. Bolt and nut type pins,such as those shown in Figures E5 and E8, are commonly used for this purpose.

B4 USAGE

When using a shackle, the following requirements apply:

(a) The strength of shackles is adversely affected by excessively elevated temperatures.

Do not use shackles outside the temperature range of -10to 200without consulting with the manufacturer.

(b)Avoid applications where movement of the load or the rope can roll and possibly unscrew the shackle pin (see Figures B1 and B2).

AS 2741:2002 pdf – Shackles