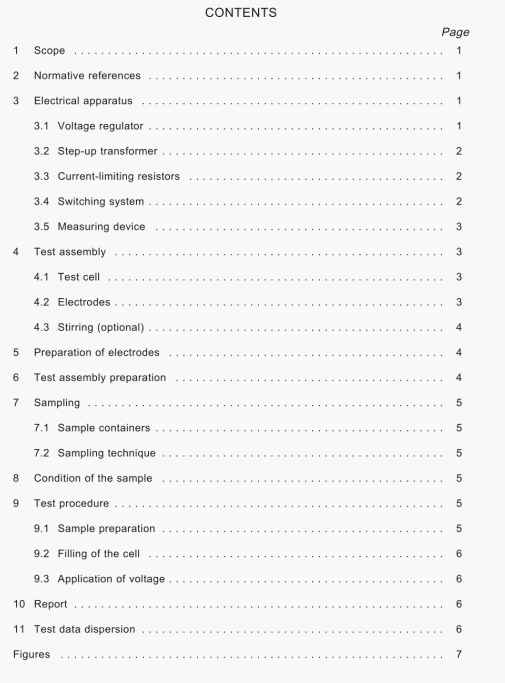

AS 1767.2.1:1999 pdf – Insulating liquids Part 2: Test methods Method 2.1: Determination of the breakdown voltage at power frequency.

Whilst current limiting as above, combined with isolation of the step-up transformer primary within 10 ms, is adequate for hydrocarbons. More satisfactory performance for silicone liquids is obtained by short circuiting of the primary circuit of the transformer by a low-impedance or by use of a low-voltage device for detection of breakdown acting within a few microseconds. This device may be of either analogue (for example, modulating amplifier) or switching (for example, thyristor) type. By the use of this device, the output voltage of the step-up transformer shall be reduced to zero within 1 ms of detection of breakdown, and shall not thereafter increase again until the next step of the test sequence is commenced.

3.5 Measuring device

For the purpose of this standard, the magnitude of the test voltage is defined as its peak value divided by ,2.

This voltage may be measured by means of a peak-voltmeter or by means of another type of voltmeter connected to the input or output side of the testing transformer, or to a special winding provided thereon; the instrument then used shall be calibrated against a standard up to the full voltage which it is desired to measure.

A method of calibration which has been found satisfactory is the use of a transfer standard. This is an auxiliary measuring device which is connected in place of the test cell between the high-voltage terminals to which it presents the same impedance as the filled test cell. The auxiliary device is separately calibrated against a primary standard, for example, a sphere gap in accordance with IEC 52 (see also IEC 60).

4 Test assembly

4.1 Test cell

The volume of the cell shall be between 350 ml and 600 ml.

The cell shall be made of material that is electrically insulating, transparent and chemically inert, resistant to the insulating liquid and the cleaning agents which may be used.

The cell shall be provided with a cover and shall be designed to permit easy removal of the electrodes for cleaning and maintenance.

Examples of suitable cell designs are given in figures 1 and 2.

4.2 Electrodes

The electrodes shall be made either of brass, bronze or austenitic stainless steel, They shall be polished and, in shape, either spherical (12,5 mm to 13,0 mm diameter) as shown in figure 1 or partially spherical of the shape and dimensions given in figure 2. The axis of the electrode system shall be horizontal, and at least 40 mm below the surface of the test liquid in the cell. No part of the electrode shall be closer than 12 mm to the cell wall or stirrer. The gap between the electrodes shall be 2.50 mm ± 0,05 mm.

AS 1767.2.1:1999 pdf – Insulating liquids Part 2: Test methods Method 2.1: Determination of the breakdown voltage at power frequency