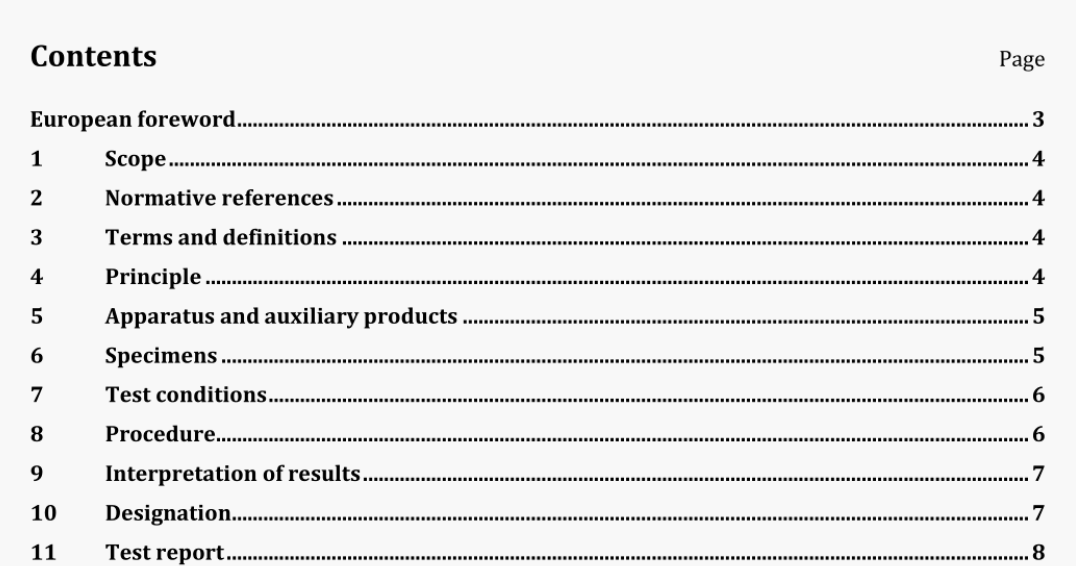

BS EN 2899:2018 pdf download.Aerospace series – Vulcanized rubbers – Test on the susceptibility to corrosion in a damp atmosphere of metals in contact with vulcanized rubbers

1 Scope

This document defines tests on the susceptibility to corrosion in a damp atmosphere of metals in contact with vulcanized rubbers.

2 Normative references

The following documents are referred to in the text in such a way that some or all of their content constitutes requirements of this document. For dated references, only the edition cited applies. For undated references, the latest edition of the referenced document (including any amendments) applies.

EN 2071,Aerospace series一Sheets in aluminium and aluminium alloys- Thickness 0,25 mm Sa S 6 mm一Dimensions

EN 22171, Steel FE-PL52S- 1 080 MPa S Rm≤1250 MPa一Sheets and plates 2 mm≤a <20 mm一Aerospace series 2

EN 2395, Aerospace series 一Aluminium alloy AL-P2014A- T4 or T42- Sheet and strip 一0,4mmSaS6mm

EN 3525, Aerospace series一Steel FE-PL1505 [15CrMoV6)一Air melted – Hardened and tempered – Plate- 6mm<a≤20 mm- 1 080 MPa≤RmS 1 280 MPa

ISO 23529, Rubber一General procedures for preparing and conditioning test pieces for physical test methods

3 Terms and definitions

For the purposes of this document, the following terms and definitions apply.

ISO and IEC maintain terminological databases for use in standardization at the following addresses:

●IEC Electropedia: available at http://www.electropedia.org/

●ISO Online browsing platform: available at http://www.iso.org/obp

3.1 contact corrosion

the visually perceptible deterioration of the metal surface in contact with rubbers, after exposure in a damp atmosphere

4 Principle

The rubber test pieces shall be directly placed after immersion in the test fluid between two test metal disks and exposed to a damp atmosphere under defined conditions. After exposure, the metal disks shall be visually examined so that deterioration due to corrosion can be noted.

6 Specimens

6.1 Metal disks

6.1.1 Material

Type 1 – Aluminium alloy AL-P2014A – T4 or T42 according to EN 2395.

Type 2 – Steel FE-PL52S – 1 080 MPa≤RmS1 250 MPa according to EN 2217.

6.1.2 Dimensions

The metal to be tested shall be circular disks of an outer diameter (120 +0,5) mm, with a (20) mm diameter hole in the centre (see Figure 1).

These disks shall be 5 mm thick minimum if they are in steel and 10 mm minimum thick if they are in aluminium so that they are not deformed when gripped.

6.1.3 Preparation

The metal disks shall have a roughness of 0,4 μm maximum on all surfaces. The edges shall be rounded.

6.1.4 Number

For each test and exposure method, use two metal disks. The two disks may be made of the same metal or of two different metals.

6.2 Rubber test pieces

6.2.1 Material

According to the material standard.

BS EN 2899:2018 pdf download