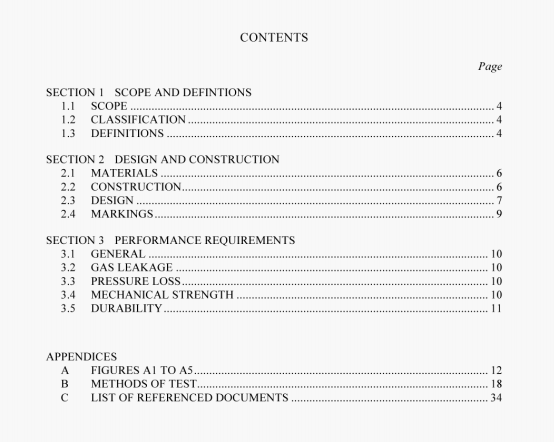

AS 4627:2005 pdf – Quick-connect devices for gas.

This test applies to all quick-connect devices.

B7.2 METHOD

The quick-connect device is tested for leakage to atmosphere, with the valve both open and closed, by means of a leak detector and air at the specited pressure.

rhere the rated working pressure of the device under test exceeds 1050 kPa a hydrostatic safety check is carried out in accordance itli M.O.T. 3.2.1(B) prior to completion of the leakage test described below.

B7.3 APPARATUS

The following apparatus, as depicted in Figure A3:

I Air inlet valve.

2 Adjustable pressure regulator.

3 Air bypass valve.

4 Leak detector suitable for maximum test pressure and capable of measuring I mlimin with an accuracy of ±0.3 mL/min e.g. bubble leak detector (see Figure A2). electronic leak detector.

5 Leak detector inlet, outlet and bypass valves.

6 Pressure gauge to indicate up to at least 1.5 times the rated working pressure or 14.0 kPa. whichever is the greater, with an accuracy of ±2% FSD.

7 Mating plug (which may be part of a hose) for quick-connect device socket.

B7.4 MATERIALS

1 Air supply at 1.5 times the rated working pressure or 14.0 kPa. whichever is the greater.

2 Soap and water solution.

B7.5 PREPARATION OF APPARATUS

1 Assemble apparatus (see Figure A3) and check for gas tightness up to inlet of quick- connect device with leak detector.

2 Seal device outlet, open manual valve or remove plug and check outlet connection for leaks with soap solution.

3 Close manual valve or replace plug.

B7.6 PROCEDURE

1 Open air bypass valve ABV and leak detector bypass valve LDB.

2 Close leak detector inlet and outlet valves LDI and LDO.

3 Open air inlet valve IV.

4 Adjust regulator AR and air bypass valve ABV to give pressure gauge reading of

1.5 times the rated working pressure or 14.0 kPa. whichever is the greater.

5 Open leak detector valves LDI and LDO. close LDH.

6 Readjust pressure as in Step 4 above, if necessary, and allow 1 mm to s(abili,e.

7 Observe leak detector.

8 Open manual valve or remove plug.

9 Observe leak detector.

H8.3 APPARATUS

1 Test rig capable of sustaining a hydrostatic test pressure of at least 1.5 times the maximum operating pressure of the device.

2 Suitable pressure gauge(s) to indicate at least the pressure in I (as above) %%ith an accuracy of ±1% FSD.

3 Hydraulic supply system capable of producing at least the test pressure in I (above).

B8.4 PREPARATION OF APPARATUS

1Install quick-connect device into the test rig as in Figure A4.

2 Open device and hold in open position.

3 Fill quick-connect device with water, completely expelling the air.

NOTE: It is essential to expel all air to reduce the potential damage caused by any sudden release of

compressed air.

4 Seal outlet of quick-connect device on test.

B8.5 PROCEI)URE

1 Close control valve CV1 and bleed valve 1W. Open all other control valves.

2 Increase the pressure slowly and steadily to 1.5 times the manufacturer’s working pressure.

3 Hold this pressure for 1 mm.

4 Observe any fracture or deformation.

AS 4627:2005 pdf – Quick-connect devices for gas