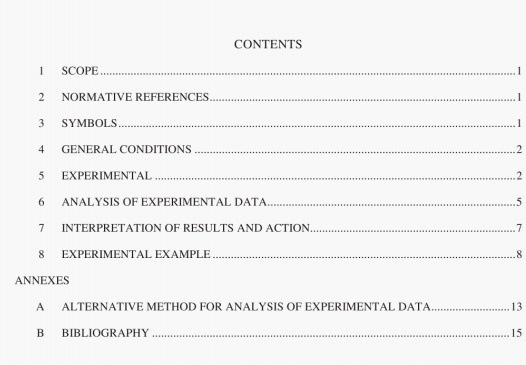

AS 2806.5:2003 pdf – Aluminium ores—Sampling Part 5: Methods for checking the precision of sampling.

7.1.1 Data containing no rogue results

When all of the values of R.. R2 and R1 calculated in accordance with 6.1 and 6.2 are within the upper control limit of the R-chart constructed in accordance with 6.1 e) and 6.2 e). it is an indication that the routine processes ot sampling, division and measurement of samples are under control

When all of the values of R calculated in accordance with 6.3 are within the uppcr control limit of the R-chart constructed in accordance with 6.3 c), it is an indication that the overall process of sampling, division and measurement is under control.

On the other horid, when iiy ol (lie VdlUe uf R. R2. R1, calculated in accordance with 6.1 and 6.2 and R. calculated in accordance with 6.3, fall outside the respective upper control limit, the process (such as sampling, preparation, or measurement) under investigation is not under control, and should be chocked in order to detect assignable causes.

7.1.2 Data containing rogue results

When a greater number of the values of or . calculated in accordance with 61, i or . calculated in accordance with h’l or I rMciilated in accordance with 6.3. is outside The control hmfls of the corresponding x-chart, it is an indication that the standard deviation of measurement or standard deviation of prepalation is ‘easonably sufficient,

When most of the values of . calculated in accordance with 6.1 and 6.2 or E calculated in accordance with 6.3 are within the control limits of the conesponding I-chart, the standard deviation of sampling is insutficient, and the variation in quality characteristics of the lots under experiment could not he detected. Under such circumstances.

AS 2806.5:2003 pdf – Aluminium ores—Sampling Part 5: Methods for checking the precision of sampling