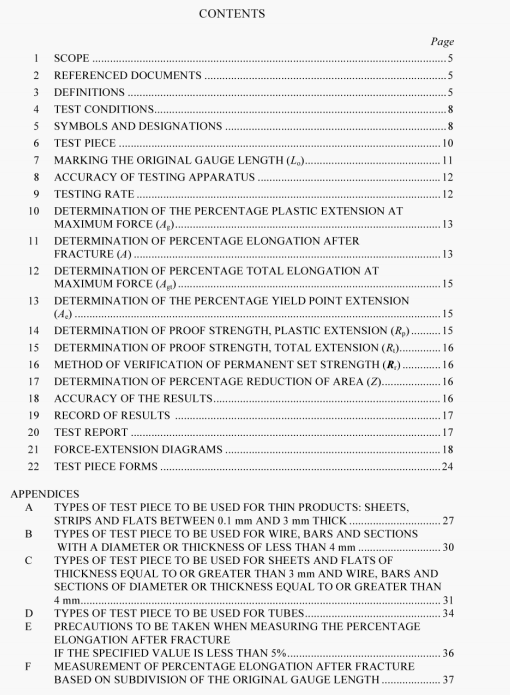

AS 1391:2005 pdf – Metallic materials—Tensile testing atambient temperature.

If the tensile test is carried out on a computer controlled testing machine having a data acquisition system. the elongation is directly determined at the maximum force.

13 DETERMINATION OF THE PERcENTA(;E YIELD POINT EXTENSION (Ar)

For materials with discontinuous yielding, the percentage yield point extension is determined from the force-extension diagram by subtracting the extension at R11 from the extension at the start of uniform work hardening. The extension at the start of uniform work hardening is defined by the intersection of a hori,ontal line through the last local minimum point, or a regression line through the range of yielding, prior to uniform work hardening and a line corresponding to the highest slope of the curve occurring at the start of uniform work hardening (see Figure 7). It is expressed as a percentage of the extensorneler gauge length L(.

14 DETERMINATION OF PROOF STREN(;TII. PLASTIC EXTENSION (R11)

The proof strength (plastic extension) is determined from the force-extension diagram by drawing a line parallel to the straight portion of the curse and at a distance from this equivalent to the prescribed plastic percentage extension, for example 0.2%. The point at which this line intersects the curve gives the force corresponding to the desired proof strength (plastic extension). The latter is obtained by dividing this force by the original cross-sectional area of the test piece (S0) (see Figure 3).

Accurate drawing of the force-extension diagram is essential.

If the straight portion of the force-extension diagram is not clearly defined, thereby preventing drawing the parallel line with sufficient precision, the following procedure is recom mended

When the presumed proof strength has been exceeded. the force is reduced to a value equal to about 10% of the force obtained. The force is then increased again until it exceeds the value obtained originally. To determine the desired proof strength a line is drawn through the hysteresis loop. A line is then drawn parallel to this line, at a distance from the corrected origin of the curve. measured along the extension axis, equal to the prescribed plastic percentage extension. The intersection of this parallel line and the force-extension curve gives the force corresponding to the proof strength. The latter is obtained by dividing this force by the original cross-sectional area of the test piece (S0) (see Figure 6).

NOTES:

1 The correction of the origin of the curve can be done by various methods. The following method is generally used: draw a line parallel to the line defined by the hysteresis loop which crosses the rising elastic part of the diagram, the slope of which is nearest to that of the loop. The point at which this line intersects the abscissa gives the corrected origin of the curve.

AS 1391:2005 pdf – Metallic materials—Tensile testing atambient temperature